Page 158 - Read Online

P. 158

Lee et al. Soft Sci 2024;4:38 https://dx.doi.org/10.20517/ss.2024.36 Page 19 of 31

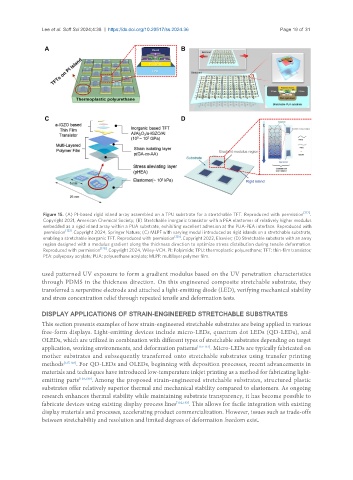

Figure 15. (A) PI-based rigid island array assembled on a TPU substrate for a stretchable TFT. Reproduced with permission [122] .

Copyright 2021, American Chemical Society; (B) Stretchable inorganic transistor with a PEA elastomer of relatively higher modulus

embedded as a rigid island array within a PUA substrate, exhibiting excellent adhesion at the PUA-PEA interface. Reproduced with

permission [123] . Copyright 2024, Springer Nature; (C) MLPF with varying moduli introduced as rigid islands on a stretchable substrate,

enabling a stretchable inorganic TFT. Reproduced with permission [125] . Copyright 2022, Elsevier; (D) Stretchable substrate with an array

region designed with a modulus gradient along the thickness direction to optimize stress distribution during tensile deformation.

Reproduced with permission [126] . Copyright 2024, Wiley-VCH. PI: Polyimide; TPU: thermoplastic polyurethane; TFT: thin-film transistor;

PEA: polyepoxy acrylate; PUA: polyurethane acrylate; MLPF: multilayer polymer film.

used patterned UV exposure to form a gradient modulus based on the UV penetration characteristics

through PDMS in the thickness direction. On this engineered composite stretchable substrate, they

transferred a serpentine electrode and attached a light-emitting diode (LED), verifying mechanical stability

and stress concentration relief through repeated tensile and deformation tests.

DISPLAY APPLICATIONS OF STRAIN-ENGINEERED STRETCHABLE SUBSTRATES

This section presents examples of how strain-engineered stretchable substrates are being applied in various

free-form displays. Light-emitting devices include micro-LEDs, quantum dot LEDs (QD-LEDs), and

OLEDs, which are utilized in combination with different types of stretchable substrates depending on target

application, working environments, and deformation patterns [127-131] . Micro-LEDs are typically fabricated on

mother substrates and subsequently transferred onto stretchable substrates using transfer printing

methods [127,128] . For QD-LEDs and OLEDs, beginning with deposition processes, recent advancements in

materials and techniques have introduced low-temperature inkjet printing as a method for fabricating light-

emitting parts [129,130] . Among the proposed strain-engineered stretchable substrates, structured plastic

substrates offer relatively superior thermal and mechanical stability compared to elastomers. As ongoing

research enhances thermal stability while maintaining substrate transparency, it has become possible to

fabricate devices using existing display process lines [132,133] . This allows for facile integration with existing

display materials and processes, accelerating product commercialization. However, issues such as trade-offs

between stretchability and resolution and limited degrees of deformation freedom exist.