Page 28 - Read Online

P. 28

Page 10 of 26 Blewitt et al. Soft Sci 2024;4:13 https://dx.doi.org/10.20517/ss.2023.49

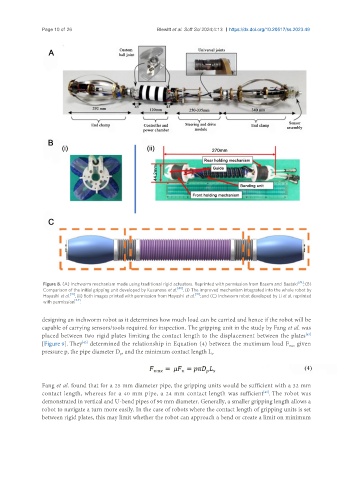

Figure 8. (A) Inchworm mechanism made using traditional rigid actuators. Reprinted with permission from Basem and Bastaki [39] ; (B)

Comparison of the initial gripping unit developed by Kusunose et al. [40] . (i) The improved mechanism integrated into the whole robot by

Hayashi et al. [41] , (ii) Both images printed with permission from Hayashi et al. [41] ; and (C) Inchworm robot developed by Li et al. reprinted

with permission [44] .

designing an inchworm robot as it determines how much load can be carried and hence if the robot will be

capable of carrying sensors/tools required for inspection. The gripping unit in the study by Fang et al. was

placed between two rigid plates limiting the contact length to the displacement between the plates

[43]

[Figure 9]. They determined the relationship in Equation (4) between the maximum load F given

[43]

max

pressure p, the pipe diameter D , and the minimum contact length L . s

p

Fang et al. found that for a 25 mm diameter pipe, the gripping units would be sufficient with a 32 mm

contact length, whereas for a 40 mm pipe, a 24 mm contact length was sufficient . The robot was

[43]

demonstrated in vertical and U-bend pipes of 90 mm diameter. Generally, a smaller gripping length allows a

robot to navigate a turn more easily. In the case of robots where the contact length of gripping units is set

between rigid plates, this may limit whether the robot can approach a bend or create a limit on minimum