Page 31 - Read Online

P. 31

Page 8 of 34 Ma et al. Soft Sci 2024;4:26 https://dx.doi.org/10.20517/ss.2024.20

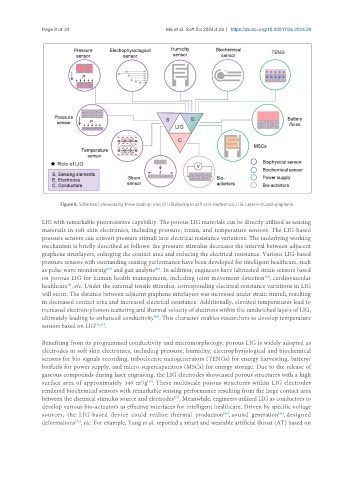

Figure 5. Schematic showcasing three leading roles of LIG playing in soft skin electronics. LIG: Laser-induced-graphene.

LIG with remarkable piezoresistive capability. The porous LIG materials can be directly utilized as sensing

materials in soft skin electronics, including pressure, strain, and temperature sensors. The LIG-based

pressure sensors can convert pressure stimuli into electrical resistance variations. The underlying working

mechanism is briefly described as follows: the pressure stimulus decreases the interval between adjacent

graphene interlayers, enlarging the contact area and reducing the electrical resistance. Various LIG-based

pressure sensors with outstanding sensing performance have been developed for intelligent healthcare, such

[60]

[60]

as pulse wave monitoring and gait analysis . In addition, engineers have fabricated strain sensors based

on porous LIG for human health management, including joint movement detection , cardiovascular

[89]

healthcare , etc. Under the external tensile stimulus, corresponding electrical resistance variations in LIG

[3]

will occur. The distance between adjacent graphene interlayers was increased under strain stimuli, resulting

in decreased contact area and increased electrical resistance. Additionally, elevated temperatures lead to

increased electron-phonon scattering and thermal velocity of electrons within the sandwiched layers of LIG,

[90]

ultimately leading to enhanced conductivity . This character enables researchers to develop temperature

sensors based on LIG [35,91] .

Benefiting from its programmed conductivity and micromorphology, porous LIG is widely adopted as

electrodes in soft skin electronics, including pressure, humidity, electrophysiological and biochemical

sensors for bio-signals recording, triboelectric nanogenerators (TENGs) for energy harvesting, battery/

biofuels for power supply, and micro-supercapacitors (MSCs) for energy storage. Due to the release of

gaseous compounds during laser engraving, the LIG electrodes showcased porous structures with a high

2

[23]

surface area of approximately 340 m /g . These multiscale porous structures within LIG electrodes

rendered biochemical sensors with remarkable sensing performance resulting from the large contact area

between the chemical stimulus source and electrodes . Meanwhile, engineers utilized LIG as conductors to

[75]

develop various bio-actuators as effective interfaces for intelligent healthcare. Driven by specific voltage

sources, the LIG-based device could realize thermal production , sound generation , designed

[45]

[46]

[32]

deformations , etc. For example, Yang et al. reported a smart and wearable artificial throat (AT) based on