Page 142 - Read Online

P. 142

Chong et al. J Mater Inf 2023;3:21 https://dx.doi.org/10.20517/jmi.2023.17 Page 11 of 18

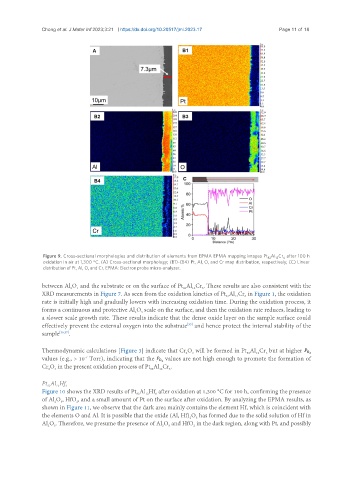

Figure 9. Cross-sectional morphologies and distribution of elements from EPMA EPMA mapping images Pt Al Cr after 100 h

82

12

6

oxidation in air at 1,300 °C. (A) Cross-sectional morphology; (B1)-(B4) Pt, Al, O, and Cr map distribution, respectively; (C) Linear

distribution of Pt, Al, O, and Cr. EPMA: Electron probe micro-analyzer.

between Al O and the substrate or on the surface of Pt Al Cr . These results are also consistent with the

2

12

6

3

82

XRD measurements in Figure 7. As seen from the oxidation kinetics of Pt Al Cr in Figure 1, the oxidation

82

6

12

rate is initially high and gradually lowers with increasing oxidation time. During the oxidation process, it

forms a continuous and protective Al O scale on the surface, and then the oxidation rate reduces, leading to

2

3

a slower scale growth rate. These results indicate that the dense oxide layer on the sample surface could

[35]

effectively prevent the external oxygen into the substrate and hence protect the internal stability of the

sample [36,37] .

Thermodynamic calculations [Figure 3] indicate that Cr O will be formed in Pt Al Cr but at higher P

6

2

o2

82

12

3

values (e.g., > 10 Torr), indicating that the P values are not high enough to promote the formation of

-7

o2

Cr O in the present oxidation process of Pt Al Cr .

12

6

82

3

2

Pt Al Hf 6

12

82

Figure 10 shows the XRD results of Pt Al Hf after oxidation at 1,300 °C for 100 h, confirming the presence

6

82

12

of Al O , HfO , and a small amount of Pt on the surface after oxidation. By analyzing the EPMA results, as

2

3

2

shown in Figure 11, we observe that the dark area mainly contains the element Hf, which is coincident with

the elements O and Al. It is possible that the oxide (Al, Hf) O has formed due to the solid solution of Hf in

2

3

Al O . Therefore, we presume the presence of Al O and HfO in the dark region, along with Pt, and possibly

3

2

2

2

3