Page 140 - Read Online

P. 140

Chong et al. J Mater Inf 2023;3:21 https://dx.doi.org/10.20517/jmi.2023.17 Page 9 of 18

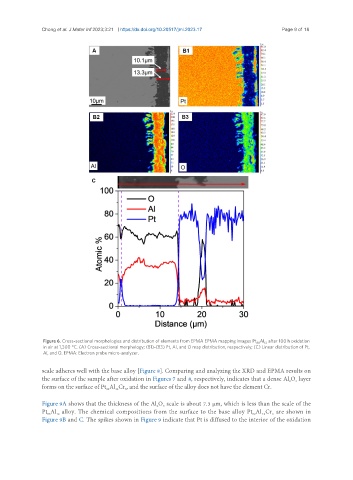

Figure 6. Cross-sectional morphologies and distribution of elements from EPMA EPMA mapping images Pt Al after 100 h oxidation

12

88

in air at 1,300 °C. (A) Cross-sectional morphology; (B1)-(B3) Pt, Al, and O map distribution, respectively; (C) Linear distribution of Pt,

Al, and O. EPMA: Electron probe micro-analyzer.

scale adheres well with the base alloy [Figure 8]. Comparing and analyzing the XRD and EPMA results on

the surface of the sample after oxidation in Figures 7 and 8, respectively, indicates that a dense Al O layer

2

3

forms on the surface of Pt Al Cr , and the surface of the alloy does not have the element Cr.

12

6

82

Figure 9A shows that the thickness of the Al O scale is about 7.3 μm, which is less than the scale of the

3

2

Pt Al alloy. The chemical compositions from the surface to the base alloy Pt Al Cr are shown in

6

12

88

12

82

Figure 9B and C. The spikes shown in Figure 9 indicate that Pt is diffused to the interior of the oxidation