Page 26 - Read Online

P. 26

Zhang et al. Chem Synth 2023;3:10 https://dx.doi.org/10.20517/cs.2022.40 Page 19 of 35

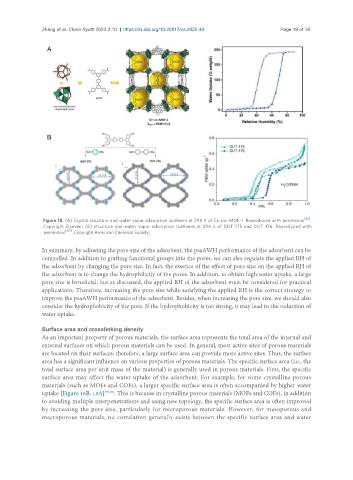

Figure 18. (A) Crystal structure and water vapor adsorption isotherm at 298 K of Cr-soc-MOF-1. Reproduced with permission [85] .

Copyright Elsevier; (B) structure and water vapor adsorption isotherm at 298 K of DUT-175 and DUT-176. Reproduced with

permission [107] . Copyright American Chemical Society.

In summary, by adjusting the pore size of the adsorbent, the psaAWH performance of the adsorbent can be

controlled. In addition to grafting functional groups into the pores, we can also regulate the applied RH of

the adsorbent by changing the pore size. In fact, the essence of the effect of pore size on the applied RH of

the adsorbent is to change the hydrophilicity of the pores. In addition, to obtain high water uptake, a large

pore size is beneficial, but as discussed, the applied RH of the adsorbent must be considered for practical

applications. Therefore, increasing the pore size while satisfying the applied RH is the correct strategy to

improve the psaAWH performance of the adsorbent. Besides, when increasing the pore size, we should also

consider the hydrophobicity of the pore. If the hydrophobicity is too strong, it may lead to the reduction of

water uptake.

Surface area and crosslinking density

As an important property of porous materials, the surface area represents the total area of the internal and

external surfaces on which porous materials can be used. In general, most active sites of porous materials

are located on their surfaces; therefore, a large surface area can provide more active sites. Thus, the surface

area has a significant influence on various properties of porous materials. The specific surface area (i.e., the

total surface area per unit mass of the material) is generally used in porous materials. First, the specific

surface area may affect the water uptake of the adsorbent. For example, for some crystalline porous

materials (such as MOFs and COFs), a larger specific surface area is often accompanied by higher water

uptake [Figure 16B, 18A] [79,85] . This is because in crystalline porous materials (MOFs and COFs), in addition

to avoiding multiple interpenetrations and using new topology, the specific surface area is often improved

by increasing the pore size, particularly for microporous materials. However, for mesoporous and

macroporous materials, no correlation generally exists between the specific surface area and water