Page 11 - Read Online

P. 11

Page 6 of 10 Ouyang et al. Microstructures 2023;3:2023027 https://dx.doi.org/10.20517/microstructures.2023.22

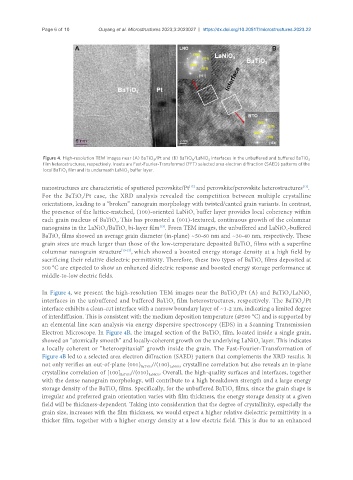

Figure 4. High-resolution TEM images near (A) BaTiO /Pt and (B) BaTiO /LaNiO interfaces in the unbuffered and buffered BaTiO 3

3

3

3

film heterostructures, respectively. Insets are Fast-Fourier-Transformed (FFT) selected area electron diffraction (SAED) patterns of the

local BaTiO film and its underneath LaNiO buffer layer.

3

3

[17]

nanostructures are characteristic of sputtered perovskite/Pt and perovskite/perovskite heterostructures .

[13]

For the BaTiO /Pt case, the XRD analysis revealed the competition between multiple crystalline

3

orientations, leading to a “broken” nanograin morphology with twisted/canted grain variants. In contrast,

the presence of the lattice-matched, (100)-oriented LaNiO buffer layer provides local coherency within

3

each grain nucleus of BaTiO . This has promoted a (001)-textured, continuous growth of the columnar

3

[13]

nanograins in the LaNiO /BaTiO bi-layer film . From TEM images, the unbuffered and LaNiO -buffered

3

3

3

BaTiO films showed an average grain diameter (in-plane) ~50-60 nm and ~30-40 nm, respectively. These

3

grain sizes are much larger than those of the low-temperature deposited BaTiO films with a superfine

3

columnar nanograin structure [13-15] , which showed a boosted energy storage density at a high field by

sacrificing their relative dielectric permittivity. Therefore, these two types of BaTiO films deposited at

3

500 °C are expected to show an enhanced dielectric response and boosted energy storage performance at

middle-to-low electric fields.

In Figure 4, we present the high-resolution TEM images near the BaTiO /Pt (A) and BaTiO /LaNiO 3

3

3

interfaces in the unbuffered and buffered BaTiO film heterostructures, respectively. The BaTiO /Pt

3

3

interface exhibits a clean-cut interface with a narrow boundary layer of ~1-2 nm, indicating a limited degree

of interdiffusion. This is consistent with the medium deposition temperature (@500 °C) and is supported by

an elemental line scan analysis via energy dispersive spectroscopy (EDS) in a Scanning Transmission

Electron Microscope. In Figure 4B, the imaged section of the BaTiO film, located inside a single grain,

3

showed an “atomically smooth” and locally-coherent growth on the underlying LaNiO layer. This indicates

3

a locally coherent or “heteroepitaxial” growth inside the grain. The Fast-Fourier-Transformation of

Figure 4B led to a selected area electron diffraction (SAED) pattern that complements the XRD results. It

not only verifies an out-of-plane (001) BaTiO3 //(100) LaNiO3 crystalline correlation but also reveals an in-plane

crystalline correlation of [100] BaTiO3 //(010) LaNiO3 . Overall, the high-quality surfaces and interfaces, together

with the dense nanograin morphology, will contribute to a high breakdown strength and a large energy

storage density of the BaTiO films. Specifically, for the unbuffered BaTiO films, since the grain shape is

3

3

irregular and preferred grain orientation varies with film thickness, the energy storage density at a given

field will be thickness-dependent. Taking into consideration that the degree of crystallinity, especially the

grain size, increases with the film thickness, we would expect a higher relative dielectric permittivity in a

thicker film, together with a higher energy density at a low electric field. This is due to an enhanced