Page 29 - Read Online

P. 29

Wang et al. Soft Sci 2024;4:41 https://dx.doi.org/10.20517/ss.2024.53 Page 11 of 43

Table 3. Comparison of different types of inkjet printing techniques

Types Materials Substrates Diameter Accuracy Ref.

Inkjet printing Ag ink (28 cP) PU fiber substrate 500 μm 133 μm [15]

Aerosol jet printing AgNPs flake ink PTFE 2.248 mm 250 μm [13]

EHD printing Ag-PCL mixed ink Glass and silicon substrates 4 mm 8 ± 0.4 μm [90]

PCL Glass microtubes 1-10 mm 80 μm [14]

Electrospinning Ultrafine polyaniline fibres - - < 5 μm [89]

PU: Polyurethane; AgNPs: silver nanoparticles; PTFE: polytetrafluoroethylene; EHD: electrohydrodynamic; PCL: polycaprolactone.

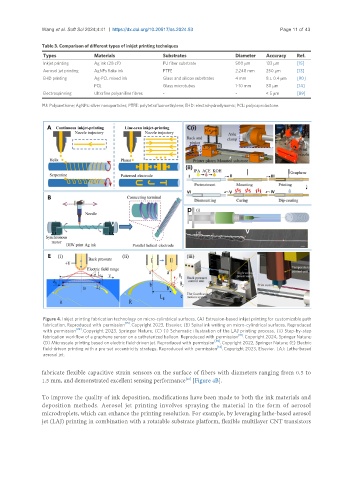

Figure 4. Inkjet printing fabrication technology on micro-cylindrical surfaces. (A) Extrusion-based inkjet printing for customizable path

[15]

fabrication. Reproduced with permission . Copyright 2023, Elsevier; (B) Spiral ink writing on micro-cylindrical surfaces. Reproduced

[29]

with permission . Copyright 2023, Springer Nature; (C) (i) Schematic illustration of the LAJ printing process. (ii) Step-by-step

[91]

fabrication workflow of a graphene sensor on a catheterized balloon. Reproduced with permission . Copyright 2024, Springer Nature;

[89]

(D) Microscale printing based on electric field-driven jet. Reproduced with permission . Copyright 2022, Springer Nature; (E) Electric

[14]

field-driven printing with a pre-set eccentricity strategy. Reproduced with permission . Copyright 2023, Elsevier. LAJ: Lathe-based

aerosol jet.

fabricate flexible capacitive strain sensors on the surface of fibers with diameters ranging from 0.5 to

[29]

1.5 mm, and demonstrated excellent sensing performance [Figure 4B].

To improve the quality of ink deposition, modifications have been made to both the ink materials and

deposition methods. Aerosol jet printing involves spraying the material in the form of aerosol

microdroplets, which can enhance the printing resolution. For example, by leveraging lathe-based aerosol

jet (LAJ) printing in combination with a rotatable substrate platform, flexible multilayer CNT transistors