Page 152 - Read Online

P. 152

Wang et al. Soft Sci. 2025, 5, 28 https://dx.doi.org/10.20517/ss.2025.11 Page 3 of 29

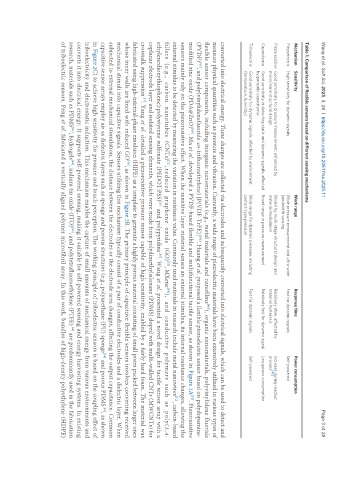

Table 1. Comparison of flexible sensors based on different sensing mechanisms

Mechanism Sensitivity Work range Response time Power consumption

Piezoelectric High sensitivity for dynamic signals Wide pressure measurement and ultra-wide Fast for dynamic signals Self-powered

bandwidth sensing

Piezoresistive Good sensitivity for pressure measurement; enhanced by Widen by multi-stage structural design and Relatively slow, affected by Increase during readout

[45]

micro/nano structural design material modulation material hysteresis process

Capacitance Good sensitivity in detecting static and dynamic signals, affected Broad range in pressure measurement Relatively fast for dynamic signal Low power consumption

by parasitic capacitance

Triboelectric Good sensitivity for dynamic signals, affected by environment Wide range for dynamic pressure, including Fast for dynamic signals Self-powered

(temperature, humidity) contact-type pressure

converted into electrical energy. These charges are collected via electrodes and subsequently converted into electrical signals, which can be used to detect and

measure physical quantities such as pressure and vibration. Currently, a wide range of piezoelectric materials have been extensively utilized in various types of

flexible sensor components, including inorganic nanomaterials (e.g., metal materials and nanofilms ), organic nanomaterials, polyvinylidene fluoride

[46]

(PVDF) , and poly(vinylidenefluoride-co-trifluoroethylene) [P(VDF-TrFE)] . Huang et al. proposed a flexible piezoelectric sensor based on polydopamine-

[48]

[47]

modified zinc oxide (PDA@ZnO) . Ma et al. developed a PVDF-based flexible and multifunctional tactile sensor, as shown in Figure 2A . Piezoresistive

[50]

[49]

sensors mainly rely on the piezoresistive effect. When the sensitive layer material senses an external stimulus, its internal resistance changes, allowing the

external stimulus to be detected by measuring the variation in resistance value. Commonly used materials in research include metal nanowires , carbon-based

[51]

fillers (e.g., carbon nanotubes (CNTs) , reduced graphene oxide (GO) , MXene ), and conductive polymers such as poly(3,4-

[54]

[53]

[52]

ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS) and polypyridine . Wang et al. presented a novel design for tactile sensor array with a

[55]

[56]

coplanar electrode layer and isolated sensing elements, which were made from polydimethylsiloxane (PDMS) doped with multi-walled CNTs (MWCNTs) for

crosstalk suppression . Yang et al. detailed a piezoresistive pressure sensor capable of high sensitivity, enabled by a fairly hard foam. The material was

[57]

fabricated using high-internal-phase emulsion (HIPE) as a template to generate a highly porous material consisting of small pores packed between larger ones

whose inner walls are lined with reduced GO , as shown in Figure 2B. The primary principle of capacitive flexible sensors involves converting received

[58]

mechanical stimuli into capacitive signals. Sensors utilizing this mechanism typically consist of a pair of conductive electrodes and a dielectric layer. When

subjected to external mechanical stimulation, the distance between the electrodes or the electrode area changes, affecting the output capacitance. Common

capacitive sensor arrays employ air as dielectric layers such as sponge and porous structures (e.g., polyurethane (PU) sponge and porous PDMS , as shown

[59]

[60]

in Figure 2C) to achieve high sensitivity for pressure and touch perception. The working principle of triboelectric sensors is based on the coupling effect of

triboelectricity and electrostatic induction. This mechanism enables the capture of small amounts of mechanical energy from various environments and

converts it into electrical energy. It supports self-powered sensing, making it suitable for self-powered sensing and energy harvesting systems. In existing

research, materials such as PDMS , hydrogels , indium tin oxide (ITO) , and polytetrafluoroethylene (PTFE) are predominantly used in the fabrication

[62]

[63]

[64]

[61]

of triboelectric sensors. Peng et al. fabricated a vertically aligned polymer microfibril array. In this work, bundles of high-density polyethylene (HDPE)