Page 143 - Read Online

P. 143

Page 4 of 31 Lee et al. Soft Sci 2024;4:38 https://dx.doi.org/10.20517/ss.2024.36

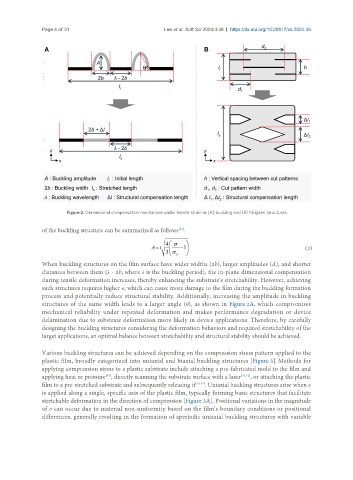

Figure 2. Dimensional compensation mechanism under tensile strain in (A) buckling and (B) Kirigami structures.

[32]

of the buckling structure can be summarized as follows .

(2)

When buckling structures on the film surface have wider widths (2b), larger amplitudes (A), and shorter

distances between them (λ - 2b, where λ is the buckling period), the in-plane dimensional compensation

during tensile deformation increases, thereby enhancing the substrate’s stretchability. However, achieving

such structures requires higher σ, which can cause more damage to the film during the buckling formation

process and potentially reduce structural stability. Additionally, increasing the amplitude in buckling

structures of the same width leads to a larger angle (θ), as shown in Figure 2A, which compromises

mechanical reliability under repeated deformation and makes performance degradation or device

delamination due to substrate deformation more likely in device applications. Therefore, by carefully

designing the buckling structures considering the deformation behaviors and required stretchability of the

target applications, an optimal balance between stretchability and structural stability should be achieved.

Various buckling structures can be achieved depending on the compression stress pattern applied to the

plastic film, broadly categorized into uniaxial and biaxial buckling structures [Figure 3]. Methods for

applying compression stress to a plastic substrate include attaching a pre-fabricated mold to the film and

[40]

applying heat or pressure , directly scanning the substrate surface with a laser [41,42] , or attaching the plastic

film to a pre-stretched substrate and subsequently releasing it [43,44] . Uniaxial buckling structures arise when σ

is applied along a single, specific axis of the plastic film, typically forming basic structures that facilitate

stretchable deformation in the direction of compression [Figure 3A]. Positional variations in the magnitude

of σ can occur due to material non-uniformity based on the film’s boundary conditions or positional

differences, generally resulting in the formation of aperiodic uniaxial buckling structures with variable