Page 34 - Read Online

P. 34

Zhu et al. Soft Sci 2024;4:17 https://dx.doi.org/10.20517/ss.2024.05 Page 21 of 38

-1

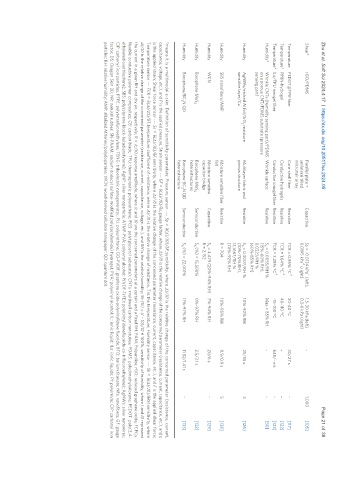

Shear* rGO/PDMS Parallel plate + Capacitive Ss = -0.0134 kPa (left), 1.5~30 kPa (left) - 1,000 [105]

-1

unilateral tilted 0.0195 kPa (right) 0.3~6 kPa (right)

microhair array

-1

Temperature PEDOT@TPU fiber Core-shell fiber Resistive TCR = 0.95% °C 20~40 °C 30/27 s - [117]

-1

Temperature* PPBN-hydrogel Conductive hydrogels Resistive TCR = 1.64% °C 40~110 °C - - [122]

Temperature* ILs/TPU ionogel fiber Conductive ionogel fiber Resistive TCR = 3.28% °C -1 -15~100 °C 645/- ms - [123]

Humidity* Wrinkle CNTs (humidity sensing part)/PDMS Wrinkle surface Resistive S = 0.0055/RH % Max = 85% RH - - [50]

h

on a porous CNT/PDMS substrate (pressure (15%-60% RH),

sensing part) 0.0323/RH %

(60%-85% RH)

Humidity AgNWs/etched Al foil/SiO moisture Multilayer fabric and Resistive S = 0.3007/RH % 10%~92% RH 25/55 s 3 [126]

2 h

sensitive layer/Cu porous structure (10%~70% RH),

13.1667/RH %

(70%~92% RH)

Humidity SBS nanofibers/AMP Moisture sensitive fiber Resistive R = 704 10%~95% RH 0.9/0.9 s 5 [138]

felt

Humidity WCN Moisture sensitive Capacitive S = 4.479 (20%~94% RH) 7%-94% RH 20/6 s - [129]

h

capacitor bridge R = 2,152

Humidity Borophene-MoS 2 Borophene-MoS 2 Semiconductive S (%) = 15,500% 0%~97% RH 2.5/3.1 s [132]

h

heterostructures

Humidity Borophene/BC N QD Borophene-BC N QD Semiconductive S (%) = 22,001% 11%~97% RH 11.82/1.41 s - [133]

2

h

2

heterostructure

*means it is a multimodal e-skin. Definition of sensitivity parameters: Pressure sensor --- Sp = δ(ΔJ/J0)/δP, sensitivity, where ΔJ/J0 is the relative change of the concerned parameter (resistance, current,

capacitance, voltage, etc.), and P is the applied pressure; Strain sensor --- GF = δ(ΔJ/J0)/δε, gauge factor, where ΔJ/J0 is the relative change of the concerned parameter (resistance, current, capacitance, etc.), and ε

is the applied strain; Shear force sensor --- Ss = δ(ΔJ/J0)/δF, sensitivity, where ΔJ/J0 is the relative change of the concerned parameter (resistance, current, capacitance, etc.), and F is the applied shear force;

Temperature sensor --- TCR = δ(ΔJ/J0)/δT, temperature coefficient of resistance, where ΔJ/J0 is the relative change of resistance, T is the temperature; Humidity sensor --- Sh = δ(ΔJ/J0)/δRH, sensitivity, where

ΔJ/J0 is the relative change of the concerned parameter (resistance, current, capacitance, voltage, etc.), and RH is the relative humidity; Sh (%) = (I − I0)/I0 × 100%, sensitivity of humidity, where I and I0 represent

the current in a given RH and dry air, respectively; R = Jc/J0, response amplitude, where Jc and J0 are the concerned parameters at a certain and a fixed RH. PANI: Polyaniline; rGO: reduced graphene oxide; FCPCs:

flexible conductive polymer composites; CB: carbon black; TPU: thermoplastic polyurethane; PGS: poly(glycerol sebacate); CNTs: multiwall carbon nanotubes; PDMS: polydimethylsiloxane; PEDOT: poly(3,4-

ethylenedioxythiophene); SBS: poly(styrene-block-butadienstyrene); AgNP: silver nanoparticle; ATMP-PVA: polyvinyl alcohol; P(VDF-TrFE): poly(vinylidenefluoride-co-trifluoroethylene); AgNWs: silver nanowires;

CIP: carbonyl iron particles; PTFE: polytetrafluoroethylene; TENG: triboelectric nanogenerator; PU: polyurethane; GO-PVDF: graphene oxide-polyvinylidene fluoride; BTO: barium titanate; NFs: nanofibers; GF: gauge

factor; DS: Dragon Skin 30; NR: natural rubber; SN-PAAM: sodium dodecyl sulfate-modified poly(acrylamide) hydrogel; PVA: polyvinyl alcohol; IL: ionic liquid; ILs: ionic liquids; PI: polyimide; CIP: carbonyl iron

particles; RH: relative humidity; AMP: alkalized MXenes/polydopamine; WCN: wood-derived cellulose nanopaper; QD: quantum dot.