Page 23 - Read Online

P. 23

Page 10 of 38 Zhu et al. Soft Sci 2024;4:17 https://dx.doi.org/10.20517/ss.2024.05

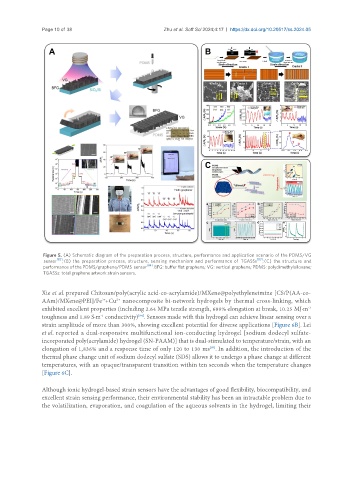

Figure 5. (A) Schematic diagram of the preparation process, structure, performance and application scenario of the PDMS/VG

sensor [82] ; (B) the preparation process, structure, sensing mechanism and performance of TGASSs [83] ; (C) the structure and

performance of the PDMS/graphene/PDMS sensor [84] . BFG: buffer flat graphene; VG: vertical graphene; PDMS: polydimethylsiloxane;

TGASSs: total graphene artwork strain sensors.

Xie et al. prepared Chitosan/poly(acrylic acid-co-acrylamide)/MXene@polyethyleneimine [CS/P(AA-co-

3+

2+

AAm)/MXene@PEI]/Fe +Cu nanocomposite bi-network hydrogels by thermal cross-linking, which

exhibited excellent properties (including 2.64 MPa tensile strength, 689% elongation at break, 10.25 MJ·m

-3

[94]

toughness and 1.89 S·m conductivity) . Sensors made with this hydrogel can achieve linear sensing over a

-1

strain amplitude of more than 300%, showing excellent potential for diverse applications [Figure 6B]. Lei

et al. reported a dual-responsive multifunctional ion-conducting hydrogel [sodium dodecyl sulfate-

incorporated poly(acrylamide) hydrogel (SN-PAAM)] that is dual-stimulated to temperature/strain, with an

[95]

elongation of 1,836% and a response time of only 120 to 130 ms . In addition, the introduction of the

thermal phase change unit of sodium dodecyl sulfate (SDS) allows it to undergo a phase change at different

temperatures, with an opaque/transparent transition within ten seconds when the temperature changes

[Figure 6C].

Although ionic hydrogel-based strain sensors have the advantages of good flexibility, biocompatibility, and

excellent strain sensing performance, their environmental stability has been an intractable problem due to

the volatilization, evaporation, and coagulation of the aqueous solvents in the hydrogel, limiting their