Page 182 - Read Online

P. 182

Page 6 of 35 Nam et al. Soft Sci 2023;3:28 https://dx.doi.org/10.20517/ss.2023.19

-1

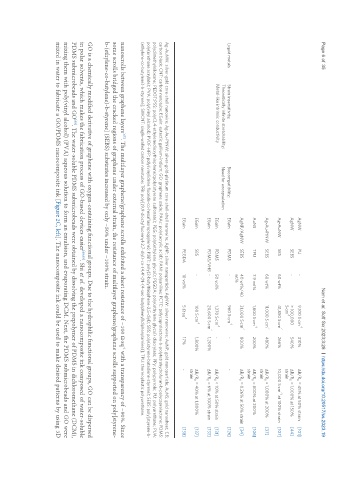

AgNW PU - 9,100 S·cm 310% ΔR/R = 45% at 50% strain [101]

0

AgNW SEBS - > 100,000 540% ΔR/R = 1,000% at 150% [44]

0

S·cm -1 strain

-1 -1

Ag-AuNW SBS 60 wt% 41,850 S·cm 266% 10,000 S·cm at 100% strain [107]

-1

Ag-Au-PtNW SEBS 60 wt% 11,000 S·cm 480% ΔR/R < 1,000% at 200% [37]

0

strain

AuNS TPU 7.9 vol% 1,600 S·cm -1 200% ΔR/R = 800% at 200% [106]

0

strain

AgNP/AgNW SEBS 40 wt%/40 31,000 S·cm -1 800% ΔR/R = 0.26% at 50% strain [34]

0

wt%

Liquid metals Strain insensitivity; Biocompatibility; EGaIn PDMS - 960 S·cm -1 - - [126]

Theoretically infinite stretchability; Need for encapsulation

Metal-like intrinsic conductivity EGaIn PDMS 50 vol% 1,370 S·cm -1 - ΔR/R < 10% at 50% strain [131]

0

EGaIn PDMS/VHB - 20,600 S·cm -1 1,200% ΔR/R = 6% at 100% strain [133]

0

EGaIn SBS - 100 S·cm -1 1,800% ΔR/R = 40% at 1,800% [137]

0

strain

EGaIn PEGDA 10 vol% 5 Ω·sq -1 17% - [138]

Ag-AuNW: silver-gold core-shell nanowire; Ag-Au-PtNW: silver-gold-platinum core-shell-shell nanowire; AgNP: silver nanoparticle; AgNW: silver nanowire; AuNP: gold nanoparticle; AuNS: gold nanosheet; CB:

carbon black; CNT: carbon nanotube; EGaIn: eutectic gallium-indium; GO: graphene oxide; PAAc: poly(acrylic acid); PANI: polyaniline; PCTC: polycaprolactone-b-polytetrahydrofuran-b-polycaprolactone; PDMS:

polydimethylsiloxane; PEDOT:PSS: poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate); PEG: poly(ethylene glycol); PEGDA: poly(ethylene glycol) diacrylate; PPy: polypyrrole; PU: polyurethane; PUA:

poly(urethane acrylate); PVA: poly(vinyl alcohol); PVDF-HFP: poly(vinylidene fluoride-co-hexafluoropropylene); P3BT: poly(3-butylthiophene-2,5-diyl); SBS: poly(styrene-butadiene-styrene); SEBS: poly[styrene-b-

(ethylene-co-butylene)-b-styrene]; SWCNT: single-walled carbon nanotube; TFB: poly[(9,9-dioctylfluorenyl-2,7-diyl)-co-(4,4’-(N-(4-sec-butylphenyl)diphenylamine)]; TPU: thermoplastic polyurethane.

[67]

-1

nanoscrolls between graphene layers . The multilayer graphene/graphene scrolls exhibited a sheet resistance of ~100 Ω·sq with a transparency of ~90%. Since

some scrolls bridged the cracked regions of graphene under external strain, the resistance of multilayer graphene/graphene scrolls supported on poly[styrene-

b-(ethylene-co-butylene)-b-styrene] (SEBS) substrates increased by only ~50% under ~100% strain.

GO is a chemically modified derivative of graphene with oxygen-containing functional groups. Due to the hydrophilic functional groups, GO can be dispersed

in polar solvents, which makes the fabrication process of GO-based devices easier [68,69] . Shi et al. developed a nanocomposite ink composed of water-soluble

PDMS submicrobeads and GO . The water-soluble PDMS submicrobeads were obtained by dissolving the prepolymer of PDMS in dichloromethane (DCM),

[68]

mixing them with poly(vinyl alcohol) (PVA) aqueous solution to form an emulsion, and evaporating DCM. Next, the PDMS submicrobeads and GO were

mixed in water to fabricate a GO/PDMS nanocomposite ink [Figure 2C, left]. The nanocomposite ink could be used to make desired patterns by using 3D