Page 181 - Read Online

P. 181

Nam et al. Soft Sci 2023;3:28 https://dx.doi.org/10.20517/ss.2023.19 Page 5 of 35

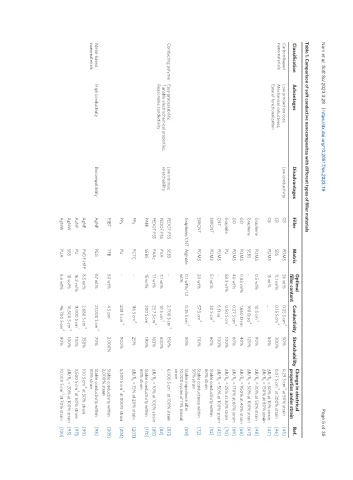

Table 1. Comparison of soft conductive nanocomposites with different types of filler materials

Optimal Change in electrical

Classification Advantages Disadvantages Filler Matrix Conductivity Stretchability Ref.

filler content properties under strain

-1 -1

Carbon-based Low production cost; Low conductivity CB PDMS 26 wt% 0.25 S·cm 50% 0.29 S·cm at 50% strain [45]

nanomaterials Mechanical robustness; CB SBS 11.1 vol% 0.15 S·cm -1 300% 0.07 S·cm at 300% strain [46]

-1

Ease of functionalization

CB PDMS 15 wt% _ 80% ΔR/R = 50% at 10% strain, [47]

0

ΔR/R = 150% at 80% strain

0

Graphene PDMS 0.5 wt% 10 S·cm -1 90% ΔR/R = 30% at 50% strain [48]

0

-1

Graphene SEBS - 100 Ω·sq 120% ΔR/R = 50% at 100% strain [67]

0

GO PDMS 0.83 vol% 1,660 Ω·cm 40% ΔR/R = 950% at 40% strain [68]

0

GO PDMS 40 wt% 0.27 S·cm -1 60% ΔR/R = 170% at 60% strain [69]

0

-1

Graphite PU 83.3 wt% 0.50 S·cm 100% ΔR/R = 25% at 30% strain [70]

0

-1

CNT PDMS - 6 Ω·sq 100% ΔR/R = 50% at 100% strain [43]

0

SWCNT PDMS 5.1 wt% 30 S·cm -1 60% Stable conductivity within [52]

60% strain

SWCNT PDMS 20 wt% 57 S·cm -1 110% Stable conductance within [72]

50% strain

Graphene/CNT Alginate 0.1 wt%/1.2 0.35 S·cm -1 50% Stable impedance after [59]

wt% 10,000 cycles of 11% biaxial

strain

-1 -1

Conducting polymer Easy processability; Low intrinsic PEDOT:PSS SEBS - 2,700 S·cm 150% 6,000 S·cm at 100% strain [87]

Tunable electrochemical properties; stretchability PEDOT:PSS PVA 7.1 wt% 10 S·cm -1 600% - [83]

Reasonable conductivity

PEDOT:PSS PAAc 1.1 wt% 23.7 S·cm -1 163% ΔR/R = 10% at 100% strain [85]

0

-1

PANI SEBS 15 vol% 200 S·cm 180% Stable conductivity within [170]

60% strain

-1

PPy PCTC - 116 S·cm 25% ΔR/R = 15% at 20% strain [203]

0

-1 -1

PPy PU - 238 S·cm 900% 5,300 S·cm at 800% strain [204]

-1

P3BT TFB 50 wt% 4 S·cm 2,000% Stable conductivity within [205]

2,000% strain

Metal-based High conductivity Biocompatibility AgNP PEG 67 wt% 21,000 S·cm -1 70% Stable conductivity within [98]

nanomaterials 50% strain

-1

AgNP PVDF-HFP 8.5 wt% 2,680 S·cm -1 350% 100 S·cm at 50% strain [99]

-1 -1

AuNP PU 16.2 vol% 11,000 S·cm 110% 3,500 S·cm at 60% strain [97]

AgNW SBS 18 vol% 10,500 S·cm -1 100% ΔR/R = 20% at 100% strain [93]

0

-1 -1

AgNW PUA 6.6 wt% 46,700 S·cm 80% 10,000 S·cm at 70% strain [100]