Page 120 - Read Online

P. 120

Rehman et al. Energy Mater 2024;4:400068 https://dx.doi.org/10.20517/energymater.2024.06 Page 51 of 64

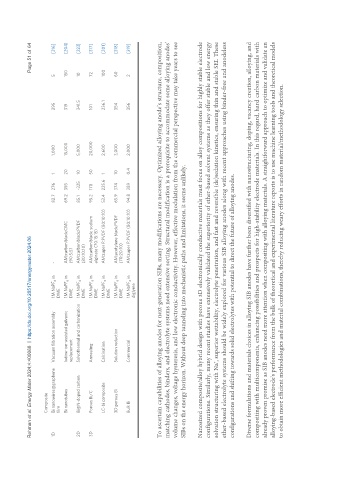

Composite

1D Bi nanowires@graphene Vacuum filtration assembly 1M NaPF in - 82.7 276 1 1,000 295 5 [316]

6

film DME

Bi nanotubes Iodine-ion-assisted galvanic 1M NaPF in AM:carbon black:CMC 69.2 355 20 15,000 319 150 [204 ]

6

replacement DME (90:5:5)

2D Bi@N-doped carbon Solvothermal and carbonization 1M NaPF in AM:carbon black:PVDF 85.1 ~325 10 5,000 341.5 10 [223]

6

DME (80:10:10)

3D Porous Bi/C Annealing 1M NaPF in AM:carbon black: sodium 95.2 178 50 20,000 101 72 [317]

6

DME alginate (70:15:15)

LC-bi composite Calcination 1M NaPF in AM:super P:PVDF (80:10:10) 53.4 225.6 1 2,600 236.1 100 [201]

6

DME

3D porous Bi Solution reduction 1M NaPF in AM:acetylene black:PVDF 65.9 374 10 3,000 354 60 [318]

6

DME (70:20:10)

Bulk Bi Commercial 1M NaPF in AM:super P:PVDF (80:10:10) 94.8 389 0.4 2,000 356 2 [319]

6

diglyme

To ascertain capabilities of alloying anodes for next-generation SIBs, many modifications are necessary. Optimized alloying anode’s structure, composition,

matching cathodes, binders, and electrolyte systems need extensive sorting. Structural modification is a prerequisite to accommodate some alloying anodes'

volume changes, voltage hysteresis, and low electronic conductivity. However, effective modulation from the commercial perspective may take years to see

SIBs on the energy horizon. Without deep tunneling into mechanistic paths and limitations, it seems unlikely.

Nanosized composite/alloy hybrid design with porous 3D electronically conductive materials must focus on alloy compositions for highly stable electrode

configurations. Similarly, many recent studies have extensively validated the superiority of ether-based solvent systems as they offer stable and low energy

+

solvation structuring with Na , superior wettability, electrolyte penetration, and fast and reversible (de)sedation kinetics, ensuring thin and stable SEI. These

ether-based electrolyte systems should be widely explored for various SIB alloying anodes along with recent approaches using binder-free and anodeless

configurations and shifting towards solid electrolytes with potential to direct the future of alloying anodes.

Diverse formulations and materials choices in alloying SIB anodes have further been diversified with nanostructuring, doping, vacancy creation, alloying, and

compositing with multicomponents, enhancing possibilities and prospects for high-stability electrode materials. In this regard, hard carbon materials with

already proven promise as SIB anodes need more attention when compositing with alloying materials. A straightforward approach to optimize and validate an

alloying-based electrode's performance from the bulk of theoretical and experimental literature reports is to use machine learning tools and theoretical models

to obtain more efficient methodologies and material combinations, thereby reducing weary efforts in random material/methodology selection.