Page 119 - Read Online

P. 119

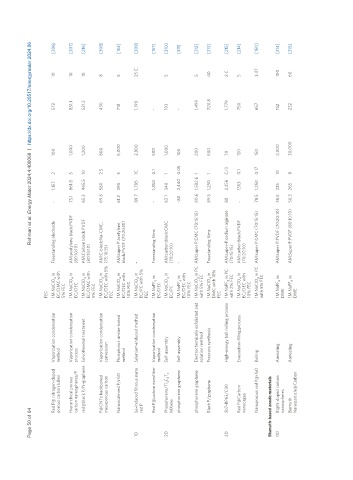

Page 50 of 64 Rehman et al. Energy Mater 2024;4:400068 https://dx.doi.org/10.20517/energymater.2024.06

FEC

Red P@ nitrogen-doped Vaporization condensation 1M NaClO in Freestanding electrode - 1,157 2 100 572 10 [306 ]

4

porous carbon tubes method EC/DMC with

5% FEC

Hierarchical porous Vaporization condensation 1M NaClO in AM:acetylene black:PVDF 75.1 861.8 5 1,000 831.1 10 [307 ]

4

carbon nanospheres/P process EC/DEC (80:10:10)

red@black P/N-graphene Solvothermal treatment 1M NaClO in AM:Carbon black:PVDF 65.3 465.5 10 1,200 521.3 10 [216]

4

EC/DMC with (80:10:10)

5% FEC

P@CNTs backboned Vaporization condensation 1M NaClO in AM:C-black:Na-CMC, 69.8 580 2.5 800 430 8 [308 ]

4

mesoporous carbon conversion EC/DEC with 5% (75:10:15)

FEC

Nanoscale red P/rGO Phosphorus-amine-based 1M NaClO 4 in AM:super P acetylene 61.2 390 5 5,000 718 5 [154]

method EC/DEC with black:PVDF (70:20:10)

10% FEC

1D Se-induced fibrous nano Selenium-induced method 1M NaClO in - 89.7 1,785 1C 2,800 1,190 25 C [309 ]

4

red P EC/PC with 5%

FEC

Red P@carbon nanofiber Vaporization condensation 1M NaPF 6 in Freestanding films - 1,850 0.1 500 - [157]

method EC/DEC

2D Phosphorene/Ti C T Self-assembly 1M NaClO in AM:carbon black:CMC 63.1 340 1 1,000 193 5 [310]

4

3 2 x

MXene EC/PC (70:20:10)

phosphorene graphene Self-assembly 1M NaPF in - ~80 2,440 0.05 100 - [311]

6

EC/DEC with

10% FEC

phosphorene graphene Electrochemically exfoliated and 1M NaClO in PC AM:super P:CMC (70:15:15) 80.6 1,582.6 1 200 1,499 5 [312]

4

solution method with 5% FEC

Black P/graphene Pressure synthesis 1M NaClO in Freestanding films 89.5 1,250 1 500 720.8 40 [313]

4

DMC with 10%

FEC

3D Sb7-RP63/C30 High-energy ball milling process 1M NaPF in PC AM:super-P:sodium alginate 88 2,356 C/3 70 1,779 2 C [215]

6

with 2% FEC (70:15:15)

Red P@Carbon Evacuation-filling process 1M NaClO in AM:carbon black:PVDF - 1363 0.1 150 750 5 [214]

4

nanocages EC/DEC with (70:20:10)

10% FEC

Nanoporous red P@rGO Boiling 1M NaClO in PC AM:super P:CMC (70:15:15) 78.5 1,250 0.17 150 657 3.47 [150]

4

with 5% FEC

Bismuth-based anode materials

0D Bi@N-doped carbon Annealing 1M NaPF in AM:super P:PVDF (70:20:10) 36.5 235 10 2,000 152 100 [314]

6

nanospheres DME

Bismuth Annealing 1M NaPF in AM:Super P:PVDF (80:10:10) 50.3 265 8 30,000 232 60 [315]

6

Nanoparticle@Carbon DME