Page 104 - Read Online

P. 104

Rehman et al. Energy Mater 2024;4:400068 https://dx.doi.org/10.20517/energymater.2024.06 Page 35 of 64

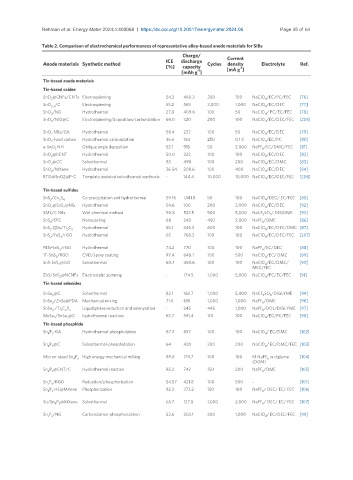

Table 2. Comparison of electrochemical performances of representative alloy-based anode materials for SIBs

Charge/ Current

Anode materials Synthetic method ICE discharge Cycles density Electrolyte Ref.

[%]

capacity

-1

-1

[mAh g ] [mA g ]

Tin-based anode materials

Tin-based oxides

SnO @CNFs/CNTs Electrospinning 54.3 460.3 200 100 NaClO /EC/PC/FEC [76]

2

4

SnO /C Electrospinning 55.2 565 2,000 1,000 NaClO /EC/DEC [77]

2-x 4

SnO /NG Hydrothermal 27.8 409.6 100 50 NaClO / PC/EC/FEC [78]

2

4

SnO /NiO@C Electrospinning/deposition/carbonization 69.0 320 200 100 NaClO /EC/DEC/FEC [205 ]

2 4

SnO NRs/GA Hydrothermal 58.4 232 100 50 NaClO /EC/DEC [79]

2

4

SnO -hard carbon Hydrothermal carbonization 36.6 184 250 0.1 C NaClO /EC/PC [80]

2 4

a-SnO NH Oblique angle deposition 53.1 915 50 2,000 NaPF /EC/DMC/FEC [81]

2

6

SnO @hCNT Hydrothermal 50.0 223 100 100 NaClO /EC/DEC [82]

2 4

SnO @CC Solvothermal 85 498 100 200 NaClO /EC/DMC [83]

4

2

SnO /MXene Hydrothermal 36.54 208.6 100 400 NaClO /EC/DEC [84]

2 4

BTO@SnO2@P-C Template assisted solvothermal synthesis - 144.4 10,000 10,000 NaClO /EC/DEC/FEC [206 ]

4

Tin-based sulfides

SnS /Co S Co-precipitation and hydrothermal 59.16 1,141.8 50 100 NaClO /DEC/ EC/FEC [85]

2 3 4 4

SnO @SnS @NG Hydrothermal 54.6 100 200 3,000 NaClO /EC/DEC [92]

2

2

4

SMS/C NBs Wet chemical method 90.8 522.5 500 5,000 NaCF SO / DEGDME [93]

3 3

SnS /EPC Nanocasting 68 340 450 2,000 NaPF /DME [86]

2

6

SnS QDs/Ti C Hydrothermal 55.1 345.3 600 100 NaClO /EC/DEC/DMC [87]

2 3 2 4

SnS /FeS /rGO Hydrothermal 65 768.3 100 100 NaClO /EC/DEC/FEC [207 ]

4

2

2

PEG-SnS /rGO Hydrothermal 74.2 770 100 100 NaPF /EC/DEC [88]

2 6

1T-SnS /RGO CVD/spray coating 97.4 648.1 100 500 NaClO /EC/ DMC [89]

4

2

SnS-SnS @GO Solvothermal 69.7 450.6 100 100 NaClO /EC/DMC/ [90]

2 4

MEC/FEC

ZnS/SnS @NCNFs Electrostatic spinning - 174.5 1,000 5,000 NaClO /PC/EC/FEC [91]

2 4

Tin-based selenides

SnSe @C Solvothermal 83.1 182.7 1,000 5,000 NaCF SO /DIGLYME [94]

2 3 3

SnSe /ZnSe@PDA Mechanical mixing 71.6 616 1,000 1,000 NaPF /DME [96]

6

2

SnSe /Ti C T Liquid phase reduction and selenylation - 245 445 1,000 NaPF /DOL/DIGLYME [97]

2 3 2 x 6

MoSe /SnSe @C hydrothermal reaction 63.7 591.4 110 100 NaClO /EC/PC/FEC [98]

4

2

2

Tin-based phosphide

Sn P -GA Hydrothermal-phosphidation 67.3 657 100 100 NaClO / EC/DMC [102 ]

4 3

4

Sn P @C Solvothermal-phosphidation 64 420 300 200 NaClO / EC/DMC/FEC [103 ]

4 3

4

Micron-sized Sn P High energy mechanical milling 89.8 719.7 100 100 M NaPF in diglyme [104]

4 3

6

(DGM)

Sn P @CNT/C Hydrothermal reaction 85.2 742 150 200 NaPF /DME [105]

4 3

6

Sn P /RGO Reduction/phosphorization 54.57 421.8 100 500 - [101]

x y

Sn P HS@MXene Phosphorization 82.3 373.2 150 100 NaPF / DEC/ EC/ FEC [106]

4 3

6

Sn/Sn P @MXene Solvothermal 65.7 127.8 1,000 2,000 NaPF / DEC/ EC/ FEC [107]

4 3

6

Sn P /NG Carbonization-phosphorization 52.6 203.1 300 1,000 NaClO / EC/DEC/FEC [99]

4

x y