Page 105 - Read Online

P. 105

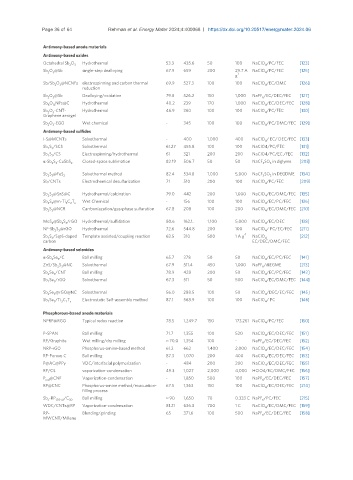

Page 36 of 64 Rehman et al. Energy Mater 2024;4:400068 https://dx.doi.org/10.20517/energymater.2024.06

Antimony-based anode materials

Antimony-based oxides

Octahedral Sb O 3 Hydrothermal 53.3 435.6 50 100 NaClO /PC/FEC [123]

4

2

Sb O @Sb single-step dealloying 67.9 659 200 29.7 A NaClO /PC/FEC [125]

2 3 1 4

g

Sb/Sb O @NCNFs electrospinning and carbon thermal 69.9 527.3 100 100 NaClO /EC/DMC [126]

2 3 4

reduction

Sb O @Sb Dealloying/oxidation 79.8 526.2 150 1,000 NaPF /EC/DEC/FEC [127]

2 3 6

Sb O NPs@C Hydrothermal 40.2 239 170 1,000 NaClO /EC/DEC/FEC [128]

6

4

13

Sb O -CNT- Hydrothermal 46.9 360 100 100 NaClO /PC/FEC [130]

2 3 4

Graphene aerogel

Sb O -EGO Wet chemical - 345 100 100 NaClO /PC/DMC/FEC [129]

2 3 4

Antimony-based sulfides

I-S@MCNTs Solvothermal - 400 1,000 400 NaClO / EC/ DEC/FEC [133]

4

Sb S /SCS Solvothermal 61.27 455.8 100 100 NaClO4/PC/FEC [131]

2 3

Sb S /CS Electrospinning/hydrothermal 61 321 200 200 NaClO4/PC/EC /FEC [132]

2 3

α-Sb S -CuSbS 2 Closed-space sublimation 82.19 506.7 50 50 NaCF SO in diglyme [208 ]

3

3

2 3

Sb S @FeS Solvothermal method 82.4 534.8 1,000 5,000 NaCF SO in DEGDME [134]

2 3 2 3 3

Sb/CNTs Electrochemical desulfurization 71 510 200 100 NaClO /PC/FEC [209 ]

4

@SnS@C Hydrothermal/calcination 79.0 442 200 1,000 NaClO /EC/DMC/FEC [135]

Sb S 3 4

2

Sb S @m-Ti C T Wet Chemical - 156 100 100 NaClO /EC/PC/FEC [136]

2 3 3 2 x 4

Sb S @NCR Carrboniazation/gas-phase sulfuration 67.8 208 100 200 NaClO /EC/DMC/FEC [210]

4

2 3

S /rGO Hydrothermal/sulfidation 80.6 162.1. 1,100 5,000 NaClO /EC/DEC [138]

MoS @Sb 2 3 4

2

NF-Sb S @rGO Hydrothermal 72.6 544.8 200 100 NaClO / PC/EC/FEC [211]

2 3 4

-1

Sb S /S@S-doped Template assisted/coupling reaction 63.5 310 500 1 A g NaClO 4 [212]

2 3

carbon EC/DEC/DMC/FEC

Antimony-based selenides

α-Sb Se /C Ball milling 65.7 378 50 50 NaClO /EC/PC/FEC [141]

2 3 4

ZnS/Sb S @NC Solvothermal 67.9 511.4 450 1,000 NaPF /diEGME [213]

2 3 6

Sb Se /CNT Ball milling 78.9 428 200 50 NaClO /EC/PC/FEC [143]

4

2

3

Sb Se /rGO Solvothermal 67.3 511 50 500 NaClO /EC/DMC/FEC [144]

2 3 4

Sb Se @rGO@NC Solvothermal 56.0 288.5 100 50 NaClO /DEC/EC/FEC [145]

2 3 4

Sb Se /Ti C T Electrostatic Self-assembly method 87.1 568.9 100 100 NaClO / PC [146]

3 2 x

3

4

2

Phosphorous-based anode materials

NPRP@RGO Typical redox reaction 78.5 1,249.7 150 173.261 NaClO /PC/FEC [150]

4

P-SPAN Ball milling 71.7 1,355 100 520 NaClO /EC/DEC/FEC [151]

4

RP/Graphite Wet milling/dry milling ≈ 70.0 1,354 100 - NaPF /EC/DEC/FEC [152]

6

NRP-rGO Phosphorus-amine-based method 61.2 662 1,400 2,000 NaClO /EC/DEC/FEC [154]

4

RP-Porous C Ball milling 87.3 1,070 200 400 NaClO /EC/DEC/FEC [153]

4

P@AC@PPy VDC/interfacial polymerization - 484 200 200 NaClO /EC/DEC/FEC [155]

4

RP/CS vaporization-condensation 49.3 1,027 2,000 4,000 HClO4/EC/DMC/FEC [156]

P @CNF Vaporization-condensation - 1,850 500 100 NaPF /EC/DEC/FEC [157]

6

red

RP@CNC Phosphorus-amine method/evacuation- 67.5 1,363 150 100 NaClO /EC/DEC/FEC [214]

4

filling process

Sb -RP /C Ball milling ≈ 90 1,650 70 0.333 C NaPF /PC/FEC [215]

x (70-x) 30 6

WDC/CNTs@RP Vaporization-condensation 81.21 636.3 700 1 C NaClO /EC/DMC/FEC [159]

4

RP- Blending/grinding 65 371.6 100 500 NaPF /EC/DEC/FEC [158]

6

MWCNT/MXene