Page 26 - Read Online

P. 26

Dang et al. Chem Synth 2023;3:14 https://dx.doi.org/10.20517/cs.2022.33 Page 7 of 20

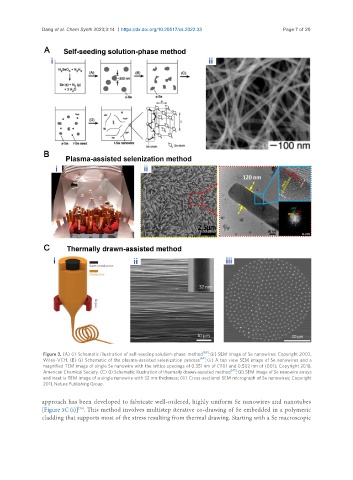

Figure 3. (A) (i) Schematic illustration of self-seeding solution-phase method [68] ; (ii) SEM image of Se nanowires; Copyright 2002,

Wiley-VCH. (B) (i) Schematic of the plasma-assisted selenization process [69] ; (ii) A top view SEM image of Se nanowires and a

magnified TEM image of single Se nanowire with the lattice spacings of 0.351 nm of (110) and 0.502 nm of (001); Copyright 2018,

American Chemical Society. (C) (i) Schematic illustration of thermally drawn-assisted method [70] ; (ii) SEM image of Se nanowire arrays

and inset is TEM image of a single nanowire with 32 nm thickness; (iii) Cross-sectional SEM micrograph of Se nanowires; Copyright

2011, Nature Publishing Group.

approach has been developed to fabricate well-ordered, highly uniform Se nanowires and nanotubes

[70]

[Figure 3C (i)] . This method involves multistep iterative co-drawing of Se embedded in a polymeric

cladding that supports most of the stress resulting from thermal drawing. Starting with a Se macroscopic