Page 11 - Read Online

P. 11

Xu et al. Microstructures 2023;3:2023015 https://dx.doi.org/10.20517/microstructures.2022.40 Page 7 of 9

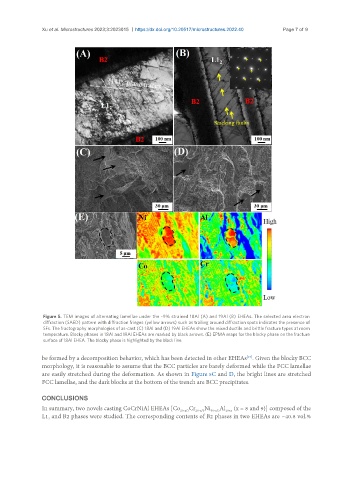

Figure 5. TEM images of alternating lamellae under the ~9% strained 18Al (A) and 19Al (B) EHEAs. The selected area electron

diffraction (SAED) pattern with diffraction fringes (yellow arrows) such as trailing around diffraction spots indicates the presence of

SFs. The fractography morphologies of as-cast (C) 18Al and (D) 19Al EHEAs show the mixed ductile and brittle fracture types at room

temperature. Blocky phases in 18Al and 19Al EHEAs are marked by black arrows. (E) EPMA maps for the blocky phase on the fracture

surface of 18Al EHEA. The blocky phase is highlighted by the black line.

be formed by a decomposition behavior, which has been detected in other EHEAs . Given the blocky BCC

[15]

morphology, it is reasonable to assume that the BCC particles are barely deformed while the FCC lamellae

are easily stretched during the deformation. As shown in Figure 5C and D, the bright lines are stretched

FCC lamellae, and the dark blocks at the bottom of the trench are BCC precipitates.

CONCLUSIONS

In summary, two novels casting CoCrNiAl EHEAs [Co 20-x/3 Cr 20-x/3 Ni 50-x/3 Al (x = 8 and 9)] composed of the

10+x

L1 and B2 phases were studied. The corresponding contents of B2 phases in two EHEAs are ~40.8 vol.%

2