Page 347 - Read Online

P. 347

Page 10 of 13 Kumar et al. Vessel Plus 2019;3:35 I http://dx.doi.org/10.20517/2574-1209.2019.006

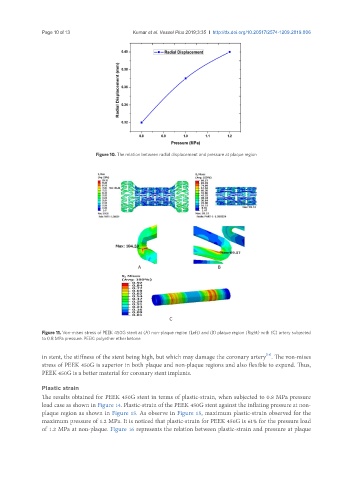

Figure 10. The relation between radial displacement and pressure at plaque region

A B

C

Figure 11. Von-mises stress of PEEK 450G stent at (A) non-plaque region (Left) and (B) plaque region (Right) with (C) artery subjected

to 0.8 MPa pressure. PEEK: polyether ether ketone

[14]

in stent, the stiffness of the stent being high, but which may damage the coronary artery . The von-mises

stress of PEEK 450G is superior in both plaque and non-plaque regions and also flexible to expand. Thus,

PEEK 450G is a better material for coronary stent implants.

Plastic strain

The results obtained for PEEK 450G stent in terms of plastic-strain, when subjected to 0.8 MPa pressure

load case as shown in Figure 14. Plastic-strain of the PEEK 450G stent against the inflating pressure at non-

plaque region as shown in Figure 15. As observe in Figure 15, maximum plastic-strain observed for the

maximum pressure of 1.2 MPa. It is noticed that plastic-strain for PEEK 450G is 61% for the pressure load

of 1.2 MPa at non-plaque. Figure 16 represents the relation between plastic-strain and pressure at plaque