Page 39 - Read Online

P. 39

Park et al. Soft Sci 2024;4:28 https://dx.doi.org/10.20517/ss.2024.22 Page 13 of 28

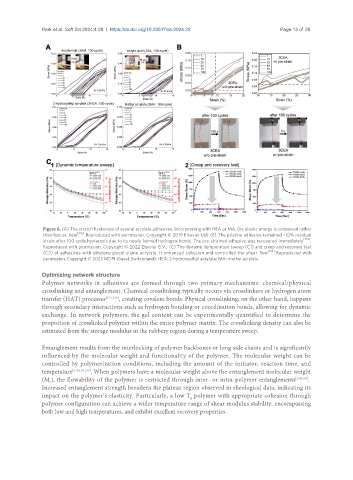

Figure 6. (A) The stretch hysteresis of several acrylate adhesives. Incorporating with HEA or MA, the elastic energy is conserved rather

than lost as heat [126] . Reproduced with permission. Copyright © 2019 Elsevier Ltd; (B) The pristine adhesive remained ~10% residual

strain after 100 cycle hysteresis due to its newly formed hydrogen bonds. The pre-strained adhesive was recovered immediately [128] .

Reproduced with permission. Copyright © 2022 Elsevier B.V.; (C) The dynamic temperature sweep (C1) and creep and recovery test

(C2) of adhesives with ethylene glycol silane acrylate. It enhanced cohesion and controlled the shear flow [132] . Reproduced with

permission. Copyright © 2023 MDPI (Basel, Switzerland). HEA: 2-hydroxyethyl acrylate; MA: methyl acrylate.

Optimizing network structure

Polymer networks in adhesives are formed through two primary mechanisms: chemical/physical

crosslinking and entanglement. Chemical crosslinking typically occurs via crosslinkers or hydrogen atom

transfer (HAT) processes [133-135] , creating covalent bonds. Physical crosslinking, on the other hand, happens

through secondary interactions such as hydrogen bonding or coordination bonds, allowing for dynamic

exchange. In network polymers, the gel content can be experimentally quantified to determine the

proportion of crosslinked polymer within the entire polymer matrix. The crosslinking density can also be

estimated from the storage modulus in the rubbery region during a temperature sweep.

Entanglement results from the interlocking of polymer backbones or long side chains and is significantly

influenced by the molecular weight and functionality of the polymer. The molecular weight can be

controlled by polymerization conditions, including the amount of the initiator, reaction time, and

temperature [130,136,137] . When polymers have a molecular weight above the entanglement molecular weight

(M ), the flowability of the polymer is restricted through inter- or intra-polymer entanglements [138,139] .

e

Increased entanglement strength broadens the plateau region observed in rheological data, indicating its

impact on the polymer’s elasticity. Particularly, a low T polymer with appropriate cohesion through

g

polymer configuration can achieve a wider temperature range of shear modulus stability, encompassing

both low and high temperatures, and exhibit excellent recovery properties.