Page 194 - Read Online

P. 194

Page 18 of 35 Nam et al. Soft Sci 2023;3:28 https://dx.doi.org/10.20517/ss.2023.19

74 MJ·m -3

-1 -1

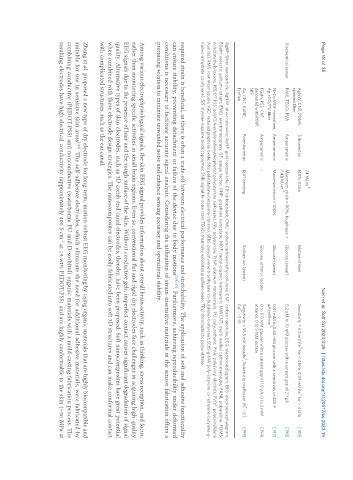

AgNW, CNT, PDMS, Triboelectric 140% strain Motion of heel Sensitivity = 5.2 mV·Pa for < 4 kPa, 0.39 mV·Pa for > 4 kPa [189]

spandex fiber

Biochemical sensor PANI, TEGO, PVA Amperometric Maximum strain ≈ 80%, toughness = Glucose (sweat) 0.2 uM to 10 mM glucose with a current gap of 2.1 μA [196]

-3

7.48 MJ·m

Ni-Co MOF nanosheet, Amperometric Maximum strain ≈ 100% Glucose (sweat) 0.01 mM to 0.66 mM glucose with a sensitivity of 425.9 [197]

-2

Ag, rGO/PU fiber μA·mM·cm

EGaIn, PSS, CNT Amperometric - Glucose, ethanol, lactate 0 to 0.5 mM glucose with a current gap of 1.9 μA, 0 to 2 mM [154]

decorated with PtNP, ethanol, 0 to 5 mM lactate

SBS

+

-1

Au, CNT, AuNP, Potentiometric 180° bending Sodium ion (sweat) Sensitivity = 55.5 mV decade , Selectivity coefficient (K : -2.1, [199]

2+

Ecoflex Ca : -3.9)

AgNP: Silver nanoparticle; AgNW: silver nanowire; AuNP: gold nanoparticle; CB: carbon black; CMC: sodium carboxymethyl cellulose; CNT: carbon nanotube; ECG: electrocardiogram; EEG: electroencephalogram;

EGaIn: eutectic gallium-indium; EMG: electromyogram; GF: gauge factor; GNP: graphene nanoplate; MOF: metal-organic framework; MWCNT: multi-walled carbon nanotube; PANI: polyaniline; PDMS:

polydimethylsiloxane; PEDOT:PSS: poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate); PPy: polypyrrole; PtNP: platinum nanoparticle; PU: polyurethane; PVA: poly(vinyl alcohol); PVDF: poly(vinylidene

fluoride); RMS: root mean square; rGO: reduced graphene oxide; SBS: poly(styrene-butadiene-styrene); SEBS: poly(styrene-b-(ethylene-co-butylene)-b-styrene); SEBS-g-MA: poly-(styrene-co- ethylene-butylene-g-

maleic-anhydride-co-styrene); SIS: styrene-isoprene block copolymer; SNR: signal-to-noise ratio; TEGO: thermally-exfoliated graphene oxide; TPU: thermoplastic polyurethane.

required strain is beneficial, as there is often a trade-off between electrical performance and stretchability. The application of soft and adhesive functionality

can ensure stability, preventing detachment or failure of the device due to body motions [156,157] . Furthermore, achieving reproducibility under deformed

conditions is necessary to facilitate accurate signal analysis. Considering the utilization of strain-insensitive materials in the sensor fabrication offers a

promising solution to minimize unwanted noise and enhance sensing accuracy and operational stability.

Among various electrophysiological signals, the skin EEG signal provides information about overall brain activity, such as thinking, stress reception, and focus,

rather than monitoring specific activities in small brain regions. Even so, conventional flat and rigid dry electrodes face challenges in acquiring high-quality

EEG signals due to the presence of hair and the rough surface of the skin. Without conductive gels, imperfect contact causes significant degradation of signal

quality. Alternative types of skin electrodes, such as 3D comb and canal electrodes, thereby, have been proposed. Soft nanocomposites have great potential

when combined with these electrode design strategies. The nanocomposites can be easily fabricated into soft 3D structures and can make conformal contact

with complicated structures, such as the ear canal.

Zhang et al. proposed a new type of dry electrode for long-term, motion-robust EEG monitoring by using organic materials that are highly biocompatible and

suitable for use in sensitive skin areas . The self-adhesive electrodes, which eliminate the need for additional adhesive materials, were fabricated by

[152]

combining conductive (PEDOT:PSS) and nonconductive (waterborne PU and D-sorbitol) organic materials with a mold-casting fabrication process. The

resulting electrodes have high electrical conductivity (approximately 400 S·cm at 19 wt% PEDOT:PSS) and are highly conformable to the skin (~50 MPa at

-1