Page 74 - Read Online

P. 74

Page 8 of 27 Yang et al. Microstructures 2023;3:2023013 https://dx.doi.org/10.20517/microstructures.2022.30

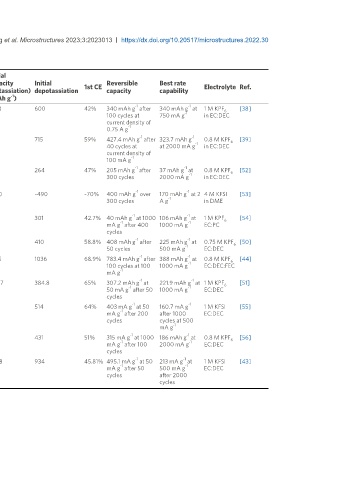

Table 1. Summary of electrochemical performance of P-based anodes for PIBs

Redox Current Initial

Anode Synthesis Modification methods potential density capacity Initial 1st CE Reversible Best rate Electrolyte Ref.

materials method (vs. K/K ) (mA g ) (potassiation) depotassiation capacity capability

+

-1

-1

(mAh g )

-1 -1

BP BP/graphite Vaporization- Hybridized with graphite ~0.5 V 250 1430 600 42% 340 mAh g after 340 mAh g at 1 M KPF [38]

-1 6

condensation 100 cycles at 750 mA g in EC:DEC

current density of

-1

0.75 A g

-1 -1

RP RP/carbon Heat treatment Hybridized with carbon 0.16-1.0 V 100 1212 715 59% 427.4 mAh g after 323.7 mAh g 0.8 M KPF [39]

-1 6

nanosheet nanosheets/design of 2D 40 cycles at at 2000 mA g in EC:DEC

nanostructure current density of

-1

100 mA g

-1 -1

Yolk-shell Hybridized with 0.05-1.2 V 100 561 264 47% 205 mAh g after 37 mAh g at 0.8 M KPF [52]

-1 6

FeP/C carbon/design of 3D 300 cycles 2000 mA g in EC:DEC

nanostructure

-1 -1

Phosphide CuP /Carbon Wet chemical and Hybridized with 100 ~700 ~490 ~70% 400 mAh g over 170 mAh g at 2 4 M KFSI [53]

2 -1

(inactive nanosphere heat treatment carbon/design of 2D 300 cycles A g in DME

metal) nanostructure

-1 -1

CoP/C Heat treatment Hybridized with carbon 0.01-1.26 V 50 706 301 42.7% 40 mAh g at 1000 106 mAh g at 1 M KPF [54]

-1 -1 6

mA g after 400 1000 mA g EC:PC

cycles

-1 -1

Phosphide SnP /C Mechanical milling Hybridized with carbon 0.01-0.8 V 50 697 410 58.8% 408 mAh g after 225 mAh g at 0.75 M KPF [50]

3 -1 6

(active 50 cycles 500 mA g EC:DEC

metal) -1 -1

Se P /C Mechanical milling Hybridized with carbon 1.3-1.9 V 50 1505 1036 68.9% 783.4 mAh g after 388 mAh g at 0.8 M KPF [44]

6

3 4

and heat 0.37 V 100 cycles at 100 1000 mA g -1 EC:DEC:FEC

-1

treatment mA g

-1 -1

Sn P /C Mechanical milling Hybridized with carbon 0.01-1.15 V 50 588.7 384.8 65% 307.2 mAh g at 221.9 mAh g at 1 M KPF [51]

6

4 3

-1

50 mA g after 50 1000 mA g -1 EC:DEC

cycles

-1 -1

Sn P /carbon Mechanical milling Hybridized with 0.01-0.5 V 50 803 514 64% 403 mA g at 50 160.7 mA g 1 M KFSI [55]

4 3 -1

fiber and carbon/design of mA g after 200 after 1000 EC:DEC

electrospinning nanostructure cycles cycles at 500

-1

mA g

-1 -1

Sn P /C Wet chemical and Hybridized with porous 0.01-0.4 V 100 845 431 51% 315 mA g at 1000 186 mAh g at 0.8 M KPF [56]

4 3 -1 -1 6

heat treatment carbon/design of 1.1-1.6 V mA g after 100 2000 mA g EC:DEC

nanostructure cycles

-1 -1

GeP Mechanical milling Nanostructural design 0.10-0.45 50 2038 934 45.81% 495.1 mA g at 50 213 mA g at 1 M KFSI [43]

5 -1 -1

V mA g after 50 500 mA g EC:DEC

cycles after 2000

cycles

CE: Coulombic efficiency.