Page 84 - Read Online

P. 84

Page 6 of 15 Duan et al. Soft Sci. 2025, 5, 4 https://dx.doi.org/10.20517/ss.2024.46

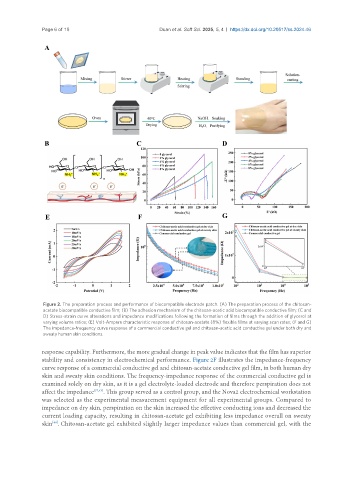

Figure 2. The preparation process and performance of biocompatible electrode patch. (A) The preparation process of the chitosan-

acetate biocompatible conductive film; (B) The adhesion mechanism of the chitosan-acetic acid biocompatible conductive film; (C and

D) Stress-strain curve alterations and impedance modifications following the formation of films through the addition of glycerol at

varying volume ratios; (E) Volt-Ampere characteristic response of chitosan-acetate (8%) flexible films at varying scan rates; (F and G)

The impedance-frequency curve response of a commercial conductive gel and chitosan-acetic acid conductive gel under both dry and

sweaty human skin conditions.

response capability. Furthermore, the more gradual change in peak value indicates that the film has superior

stability and consistency in electrochemical performance. Figure 2F illustrates the impedance-frequency

curve response of a commercial conductive gel and chitosan-acetate conductive gel film, in both human dry

skin and sweaty skin conditions. The frequency-impedance response of the commercial conductive gel is

examined solely on dry skin, as it is a gel electrolyte-loaded electrode and therefore perspiration does not

affect the impedance [37,43] . This group served as a control group, and the Nova2 electrochemical workstation

was selected as the experimental measurement equipment for all experimental groups. Compared to

impedance on dry skin, perspiration on the skin increased the effective conducting ions and decreased the

current loading capacity, resulting in chitosan-acetate gel exhibiting less impedance overall on sweaty

[44]

skin . Chitosan-acetate gel exhibited slightly larger impedance values than commercial gel, with the