Page 47 - Read Online

P. 47

Wang et al. Soft Sci 2023;3:34 https://dx.doi.org/10.20517/ss.2023.25 Page 15 of 26

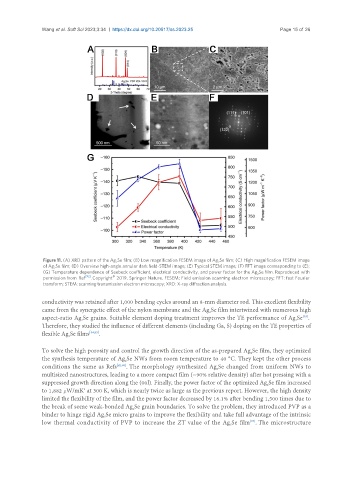

Figure 11. (A) XRD pattern of the Ag Se film; (B) Low magnification FESEM image of Ag Se film; (C) High magnification FESEM image

2 2

of Ag Se film; (D) Overview high-angle annular dark field-STEM image; (E) Typical STEM image; (F) FFT image corresponding to (E);

2

(G) Temperature dependence of Seebeck coefficient, electrical conductivity, and power factor for the Ag Se film. Reproduced with

2

[92] ©

permission from Ref . Copyright 2019. Springer Nature. FESEM: Field emission scanning electron microscopy; FFT: fast Fourier

transform; STEM: scanning transmission electron microscopy; XRD: X-ray diffraction analysis.

conductivity was retained after 1,000 bending cycles around an 8-mm diameter rod. This excellent flexibility

came from the synergetic effect of the nylon membrane and the Ag Se film intertwined with numerous high

2

aspect-ratio Ag Se grains. Suitable element doping treatment improves the TE performance of Ag Se .

[93]

2

2

Therefore, they studied the influence of different elements (including Ga, S) doping on the TE properties of

flexible Ag Se films [94,95] .

2

To solve the high porosity and control the growth direction of the as-prepared Ag Se film, they optimized

2

the synthesis temperature of Ag Se NWs from room temperature to 40 °C. They kept the other process

2

conditions the same as Refs [92,96] . The morphology synthesized Ag Se changed from uniform NWs to

2

multisized nanostructures, leading to a more compact film (~90% relative density) after hot pressing with a

suppressed growth direction along the (00l). Finally, the power factor of the optimized Ag Se film increased

2

2

to 1,882 μW/mK at 300 K, which is nearly twice as large as the previous report. However, the high density

limited the flexibility of the film, and the power factor decreased by 16.1% after bending 1,500 times due to

the break of some weak-bonded Ag Se grain boundaries. To solve the problem, they introduced PVP as a

2

binder to hinge rigid Ag Se micro grains to improve the flexibility and take full advantage of the intrinsic

2

[97]

low thermal conductivity of PVP to increase the ZT value of the Ag Se film . The microstructure

2