Page 191 - Read Online

P. 191

Page 6 of 12 Wu et al. Soft Sci 2023;3:35 https://dx.doi.org/10.20517/ss.2023.26

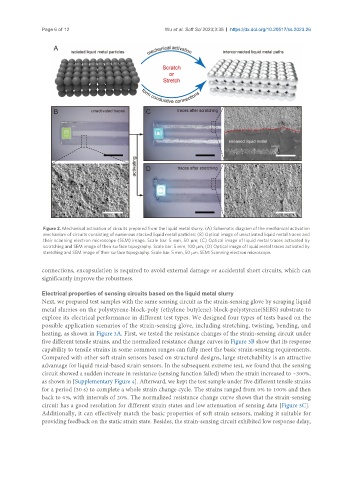

Figure 2. Mechanical activation of circuits prepared from the liquid metal slurry. (A) Schematic diagram of the mechanical activation

mechanism of circuits consisting of numerous stacked liquid metal particles; (B) Optical image of unactivated liquid metal traces and

their scanning electron microscope (SEM) image. Scale bar: 5 mm, 50 μm; (C) Optical image of liquid metal traces activated by

scratching and SEM image of their surface topography. Scale bar: 5 mm, 100 μm; (D) Optical image of liquid metal traces activated by

stretching and SEM image of their surface topography. Scale bar: 5 mm, 50 μm. SEM: Scanning electron microscope.

connections, encapsulation is required to avoid external damage or accidental short circuits, which can

significantly improve the robustness.

Electrical properties of sensing circuits based on the liquid metal slurry

Next, we prepared test samples with the same sensing circuit as the strain-sensing glove by scraping liquid

metal slurries on the polystyrene-block-poly (ethylene butylene)-block-polystyrene(SEBS) substrate to

explore its electrical performance in different test types. We designed four types of tests based on the

possible application scenarios of the strain-sensing glove, including stretching, twisting, bending, and

heating, as shown in Figure 3A. First, we tested the resistance changes of the strain-sensing circuit under

five different tensile strains, and the normalized resistance change curves in Figure 3B show that its response

capability to tensile strains in some common ranges can fully meet the basic strain-sensing requirements.

Compared with other soft strain sensors based on structural designs, large stretchability is an attractive

advantage for liquid metal-based strain sensors. In the subsequent extreme test, we found that the sensing

circuit showed a sudden increase in resistance (sensing function failed) when the strain increased to ~300%,

as shown in [Supplementary Figure 4]. Afterward, we kept the test sample under five different tensile strains

for a period (30 s) to complete a whole strain change cycle. The strains ranged from 0% to 100% and then

back to 0%, with intervals of 20%. The normalized resistance change curve shows that the strain-sensing

circuit has a good resolution for different strain states and low attenuation of sensing data [Figure 3C].

Additionally, it can effectively match the basic properties of soft strain sensors, making it suitable for

providing feedback on the static strain state. Besides, the strain-sensing circuit exhibited low response delay,