Page 42 - Read Online

P. 42

Park et al. J Mater Inf 2023;3:5 https://dx.doi.org/10.20517/jmi.2022.37 Page 5 of 25

Table 2. Compositions used in the present experimental investigation

Experimental technique

Sample Composition Differential scanning Contact angle Electromagnetic levitation

(X )

Sn

calorimetry measurement technique

I 0.365 Yes Yes Yes

II 0.414 Yes Yes No

III 0.523 Yes Yes No

IV 0.653 Yes Yes No

V 0.727 Yes Yes No

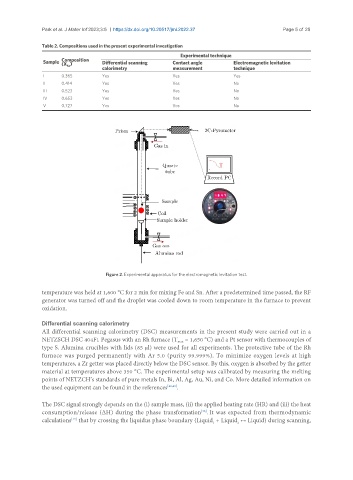

Figure 2. Experimental apparatus for the electromagnetic levitation test.

temperature was held at 1,600 °C for 2 min for mixing Fe and Sn. After a predetermined time passed, the RF

generator was turned off and the droplet was cooled down to room temperature in the furnace to prevent

oxidation.

Differential scanning calorimetry

All differential scanning calorimetry (DSC) measurements in the present study were carried out in a

NETZSCH DSC 404F1 Pegasus with an Rh furnace (T = 1,650 °C) and a Pt sensor with thermocouples of

max

type S. Alumina crucibles with lids (85 µl) were used for all experiments. The protective tube of the Rh

furnace was purged permanently with Ar 5.0 (purity 99.999%). To minimize oxygen levels at high

temperatures, a Zr getter was placed directly below the DSC sensor. By this, oxygen is absorbed by the getter

material at temperatures above 350 °C. The experimental setup was calibrated by measuring the melting

points of NETZCH’s standards of pure metals In, Bi, Al, Ag, Au, Ni, and Co. More detailed information on

the used equipment can be found in the references [48,49] .

The DSC signal strongly depends on the (i) sample mass, (ii) the applied heating rate (HR) and (iii) the heat

consumption/release (∆H) during the phase transformation . It was expected from thermodynamic

[48]

calculations that by crossing the liquidus phase boundary (Liquid + Liquid ↔ Liquid) during scanning,

[19]

2

1