Page 34 - Read Online

P. 34

Page 18 of 35 Tao et al. Energy Mater 2022;2:200036 https://dx.doi.org/10.20517/energymater.2022.46

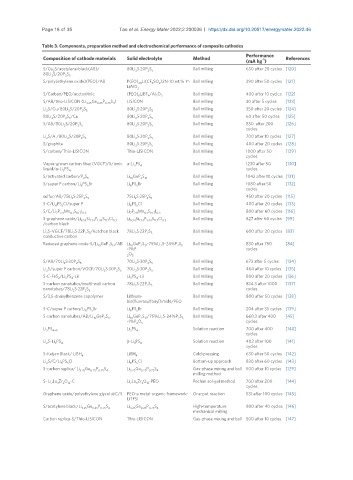

Table 3. Components, preparation method and electrochemical performance of composite cathodes

Performance

Composition of cathode materials Solid electrolyte Method -1 References

(mA hg )

S/Cu S/acetylene-black(AB)/ 80Li S·20P S Ball milling 650 after 20 cycles [120]

2 2 2 5

80Li S/20P S

2 5

2

S/poly(ethylene oxide)(PEO)/AB P(EO) Li(CF SO )2N-10 wt.% ϒ- Ball milling 290 after 50 cycles [121]

20 3 2

LiAlO 2

S/Carbon/PEO/acetonitrile (PEO) LiBF /Al O 3 Ball milling 400 after 10 cycles [122]

6

2

4

S/AB/thio-LISICON (Li Ge P S ) LISICON Ball milling 30 after 5 cycles [123]

3.25 0.25 0.75 4

Li S/Cu/80Li S/20P S 80Li S·20P S Ball milling 350 after 20 cycles [124]

2

2

2 5

2

2 5

80Li S/20P S /Cu 80Li S·20P S Ball milling 60 after 50 cycles [125]

2 2 5 2 2 5

S/AB/80Li S/20P S 80Li S·20P S Ball milling 850 after 200 [126]

2 5

2

2

2 5

cycles

Li S/A /80Li S/20P S 80Li S·20P S Ball milling 700 after 10 cycles [127]

2

2

2 5

2

2 5

S/graphite 80Li S·20P S Ball milling 400 after 20 cycles [128]

2 2 5

S/carbon/Thio-LISICON Thio-LISICON Ball milling 1000 after 50 [129]

cycles

Vapor-grown carbon fiber (VGCF)/S/ionic α-Li PS 4 Ball milling 1230 after 50 [130]

3

liquid/α-Li PS 4 cycles

3

S/activated carbon/P S Li GeP S Ball milling 1042 after 10 cycles [131]

2 5 10 2 12

S/super P carbon/Li PS Br Li PS Br Ball milling 1080 after 50 [132]

5

6

5

6

cycles

sulfur/AB/75Li S·25P S 75Li S·25P S Ball milling 450 after 20 cycles [115]

2

2 5

2

2 5

S-C/Li PS Cl/super P Li PS Cl Ball milling 400 after 20 cycles [133]

6 5 6 5

S/C/Li P Mn S I Li P Mn S I Ball milling 800 after 60 cycles [116]

0.1 10.7 0.3

7 2.9

7 2.9

0.1 10.7 0.3

S-graphene oxide/Li Si P S Cl Li Si P S Cl Ball milling 827 after 60 cycles [99]

9.54 1.74 1.44 11.7 0.3 9.54 1.74 1.44 11.7 0.3

/carbon black

Li S-VGCF/78Li S·22P S /Ketchen black 78Li S·22P S Ball milling 600 after 20 cycles [83]

2 5

2

2

2

2 5

conductive carbon

Reduced graphene oxide-S/Li GeP S /AB Li GeP S -75%Li S-24%P S Ball milling 830 after 750 [84]

10

2 12

2 12

10

2 5

2

-1%P cycles

O

2 5

S/AB/70Li S·30P S 70Li S·30P S Ball milling 673 after 5 cycles [134]

2 2 5 2 2 5

Li S/super P carbon/VGCF/70Li S·30P S 70Li S·30P S Ball milling 464 after 10 cycles [135]

2

2

2

2 5

2 5

S-C-FeS /Li PS -LiI Li PS -LiI Ball milling 800 after 20 cycles [136]

2 3 4 3 4

S-carbon nanotubes/multi-wall carbon 78Li S·22P S Ball milling 834.3 after 1000 [137]

2

2 5

nanotubes/78Li S·22P S cycles

2 2 5

S/3,5-divinylbenzene copolymer Lithium- Ball milling 800 after 50 cycles [138]

bis(fluorosulfonyl)imide/PEO

S-C/super P carbon/Li PS Br Li PS Br Ball milling 204 after 35 cycles [139]

6

5

6

5

S-carbon nanotubes/AB/Li GeP S Li GeP S /75%Li S-24%P S Ball milling 660.3 after 400 [45]

2

2 5

2 12

2 12

10

10

-1%P O cycles

2 5

Li PS 4+5 Li PS 4 Solution reaction 700 after 400 [140]

3

3

cycles

Li S-Li PS 4 β-Li PS 4 Solution reaction 402 after 100 [141]

3

2

3

cycles

S-Ketjen Black/ LiBH 4 LiBH 4 Cold-pressing 630 after 50 cycles [142]

Li S/C/Li PS Cl Li PS Cl Bottom-up approach 830 after 60 cycles [143]

2 6 5 6 5

S

S-carbon replica/ Li 3.25 Ge 0.25 0.75 4 Li 3.25 Ge 0.25 0.75 4 Gas-phase mixing and ball 500 after 10 cycles [129]

S

P

P

milling method

S- Li La Zr O -C Li La Zr O -PEO Pechini sol-gel method 700 after 200 [144]

3

2

12

2

3

7

12

7

cycles

Graphene oxide/polyethylene glycol @C/S PEO-a metal-organic framework- One-pot reaction 531 after 100 cycles [145]

LiTFSI

S/acetylene black/Li Ge P S Li Ge P S High-temperature 800 after 40 cycles [146]

3.25 0.25 0.75 4 3.25 0.25 0.75 4

mechanical milling

Carbon replica-S/Thio-LISICON Thio-LISICON Gas-phase mixing and ball 500 after 10 cycles [147]