Page 119 - Read Online

P. 119

Liang et al. Energy Mater 2023;3:300006 https://dx.doi.org/10.20517/energymater.2022.63 Page 7 of 14

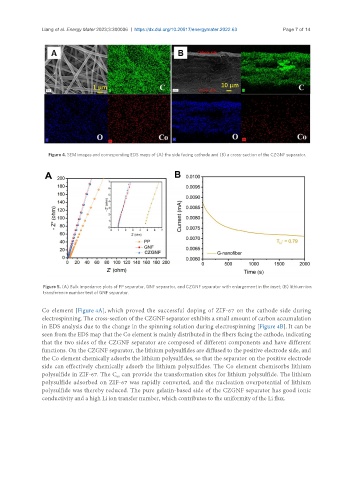

Figure 4. SEM images and corresponding EDS maps of (A) the side facing cathode and (B) a cross-section of the CZGNF separator.

Figure 5. (A) Bulk impedance plots of PP separator, GNF separator, and CZGNF separator with enlargement in the inset; (B) lithium-ion

transference number test of GNF separator.

Co element [Figure 4A], which proved the successful doping of ZIF-67 on the cathode side during

electrospinning. The cross-section of the CZGNF separator exhibits a small amount of carbon accumulation

in EDS analysis due to the change in the spinning solution during electrospinning [Figure 4B]. It can be

seen from the EDS map that the Co element is mainly distributed in the fibers facing the cathode, indicating

that the two sides of the CZGNF separator are composed of different components and have different

functions. On the CZGNF separator, the lithium polysulfides are diffused to the positive electrode side, and

the Co element chemically adsorbs the lithium polysulfides, so that the separator on the positive electrode

side can effectively chemically adsorb the lithium polysulfides. The Co element chemisorbs lithium

polysulfide in ZIF-67. The C can provide the transformation sites for lithium polysulfide. The lithium

60

polysulfide adsorbed on ZIF-67 was rapidly converted, and the nucleation overpotential of lithium

polysulfide was thereby reduced. The pure gelatin-based side of the CZGNF separator has good ionic

conductivity and a high Li ion transfer number, which contributes to the uniformity of the Li flux.