Page 8 - Read Online

P. 8

Zhu et al. HA in tissue engineering

Modification site

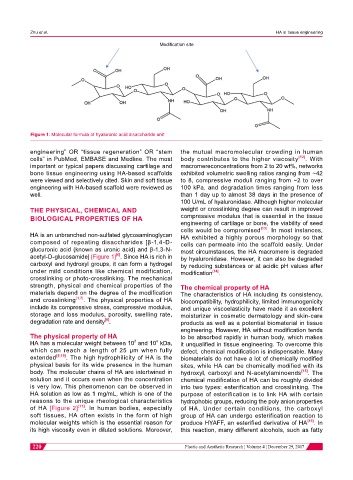

Figure 1: Molecular formula of hyaluronic acid disaccharide unit

engineering” OR “tissue regeneration” OR “stem the mutual macromolecular crowding in human

cells” in PubMed, EMBASE and Medline. The most body contributes to the higher viscosity [12] . With

important or typical papers discussing cartilage and macromereconcentrations from 2 to 20 wt%, networks

bone tissue engineering using HA-based scaffolds exhibited volumetric swelling ratios ranging from ~42

were viewed and selectively cited. Skin and soft tissue to 8, compressive moduli ranging from ~2 to over

engineering with HA-based scaffold were reviewed as 100 kPa, and degradation times ranging from less

well. than 1 day up to almost 38 days in the presence of

100 U/mL of hyaluronidase. Although higher molecular

THE PHYSICAL, CHEMICAL AND weight or crosslinking degree can result in improved

BIOLOGICAL PROPERTIES OF HA compressive modulus that is essential in the tissue

engineering of cartilage or bone, the viability of seed

cells would be compromised [13] . In most instances,

HA is an unbranched non-sulfated glycosaminoglycan HA exhibited a highly porous morphology so that

composed of repeating disaccharides [β-1,4-D- cells can permeate into the scaffold easily. Under

glucuronic acid (known as uronic acid) and β-1,3-N- most circumstances, the HA macromere is degraded

[6]

acetyl-D-glucosamide] [Figure 1] . Since HA is rich in by hyaluronidase. However, it can also be degraded

carboxyl and hydroxyl groups, it can form a hydrogel by reducing substances or at acidic pH values after

under mild conditions like chemical modification, modification [14] .

crosslinking or photo-crosslinking. The mechanical

strength, physical and chemical properties of the The chemical property of HA

materials depend on the degree of the modification The characteristics of HA including its consistency,

and crosslinking [1,7] . The physical properties of HA biocompatibility, hydrophilicity, limited immunogenicity

include its compressive stress, compressive modulus, and unique viscoelasticity have made it an excellent

storage and loss modulus, porosity, swelling rate, moisturizer in cosmetic dermatology and skin-care

[8]

degradation rate and density . products as well as a potential biomaterial in tissue

engineering. However, HA without modification tends

The physical property of HA to be absorbed rapidly in human body, which makes

3

4

HA has a molecular weight between 10 and 10 kDa, it unqualified in tissue engineering. To overcome this

which can reach a length of 25 μm when fully defect, chemical modification is indispensable. Many

extended [9,10] . The high hydrophilicity of HA is the biomaterials do not have a lot of chemically modified

physical basis for its wide presence in the human sites, while HA can be chemically modified with its

body. The molecular chains of HA are intertwined in hydroxyl, carboxyl and N-acetylaminoends [15] . The

solution and it occurs even when the concentration chemical modification of HA can be roughly divided

is very low. This phenomenon can be observed in into two types: esterification and crosslinking. The

HA solution as low as 1 mg/mL, which is one of the purpose of esterification is to link HA with certain

reasons to the unique rheological characteristics hydrophobic groups, reducing the poly anion properties

of HA [Figure 2] [11] . In human bodies, especially of HA. Under certain conditions, the carboxyl

soft tissues, HA often exists in the form of high group of HA can undergo esterification reaction to

molecular weights which is the essential reason for produce HYAFF, an esterified derivative of HA [16] . In

its high viscosity even in diluted solutions. Moreover, this reaction, many different alcohols, such as fatty

220 Plastic and Aesthetic Research ¦ Volume 4 ¦ December 29, 2017