Page 95 - Read Online

P. 95

Page 20 of 45 Mooraj et al. J Mater Inf 2023;3:4 https://dx.doi.org/10.20517/jmi.2022.41

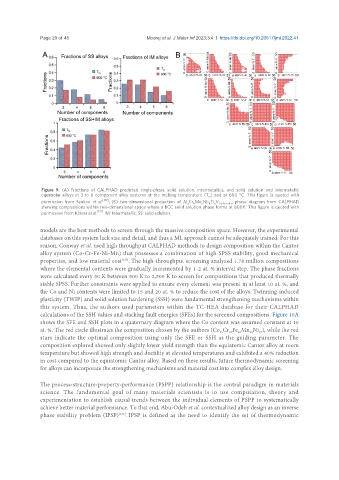

Figure 9. (A) Fractions of CALPHAD predicted single-phase solid solution, intermetallics, and solid solution and intermetallic

equimolar alloys in 3 to 6 component alloy systems at the melting temperature (T ) and at 600 °C. This figure is quoted with

m

[130]

permission from Senkov et al. ; (B) two-dimensional projection of Al Cr Mo Nb Ti V phase diagram from CALPHAD

a b c d e 1-a-b-c-d-e

showing compositions within two-dimensional space where a BCC solid solution phase forms at 800K. This figure is quoted with

[131]

permission from Klaver et al. . IM: Intermetallic; SS: solid solution.

models are the best methods to screen through the massive composition space. However, the experimental

databases on this system lack size and detail, and thus a ML approach cannot be adequately trained. For this

reason, Conway et al. used high throughput CALPHAD methods to design composition within the Cantor

alloy system (Co-Cr-Fe-Ni-Mn) that possesses a combination of high SPSS stability, good mechanical

properties, and low material cost . The high-throughput screening analyzed 1.78 million compositions

[135]

where the elemental contents were gradually incremented by 1-2 at. % interval step. The phase fractions

were calculated every 50 K between 500 K to 2,500 K to screen for compositions that produced thermally

stable SPSS. Further constraints were applied to ensure every element was present in at least 10 at. %, and

the Co and Ni contents were limited to 15 and 20 at. % to reduce the cost of the alloys. Twinning-induced

plasticity (TWIP) and solid solution hardening (SSH) were fundamental strengthening mechanisms within

this system. Thus, the authors used parameters within the TC-HEA database for their CALPHAD

calculations of the SSH values and stacking fault energies (SFEs) for the screened compositions. Figure 10A

shows the SFE and SSH plots in a quaternary diagram where the Co content was assumed constant at 10

at. %. The red circle illustrates the composition chosen by the authors (Co Cr Fe Mn Ni ), while the red

18

17

10

12

43

stars indicate the optimal composition using only the SFE or SSH as the guiding parameter. The

composition explored showed only slightly lower yield strength than the equiatomic Cantor alloy at room

temperature but showed high strength and ductility at elevated temperatures and exhibited a 40% reduction

in cost compared to the equiatomic Cantor alloy. Based on these results, future thermodynamic screening

for alloys can incorporate the strengthening mechanisms and material cost into complex alloy design.

The process-structure-property-performance (PSPP) relationship is the central paradigm in materials

science. The fundamental goal of many materials scientists is to use computation, theory and

experimentation to establish causal trends between the individual elements of PSPP to systematically

achieve better material performance. To that end, Abu-Odeh et al. contextualized alloy design as an inverse

phase stability problem (IPSP) . IPSP is defined as the need to identify the set of thermodynamic

[136]